new category

Plastic bottle cap inkjet printer to help you

by:Arojet

2021-08-07

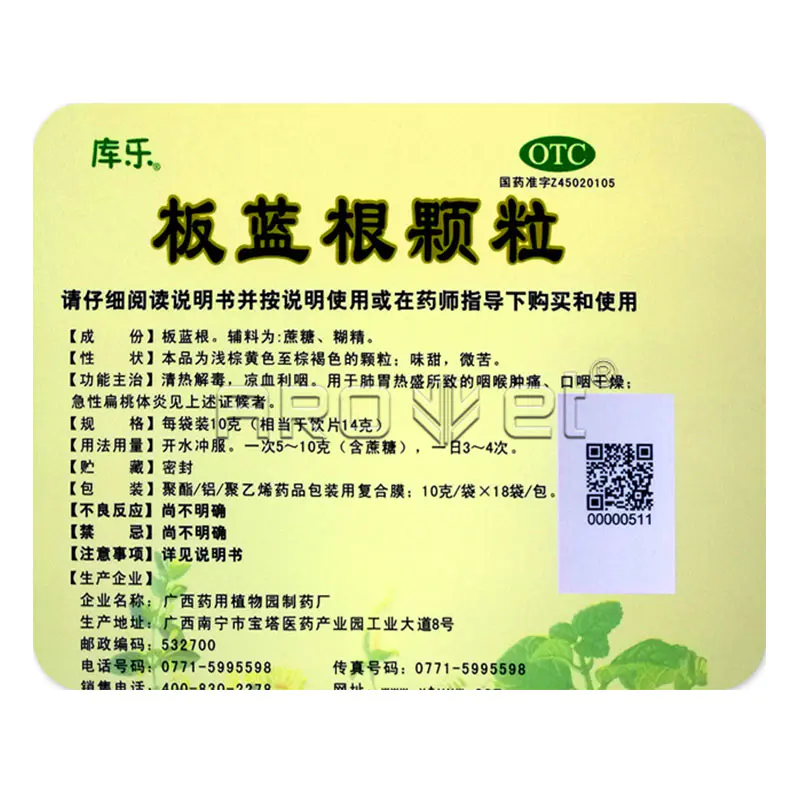

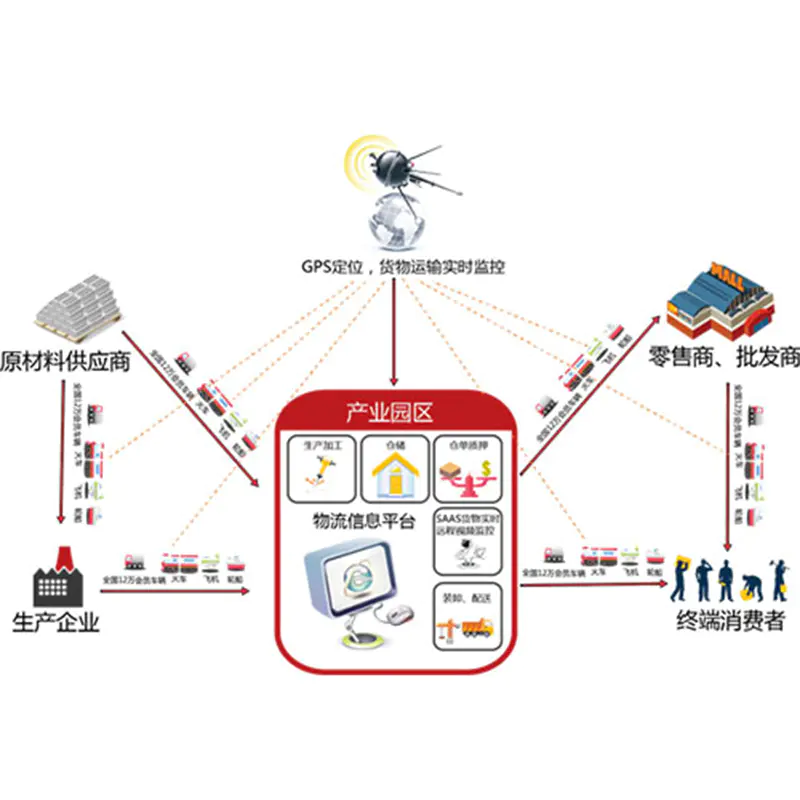

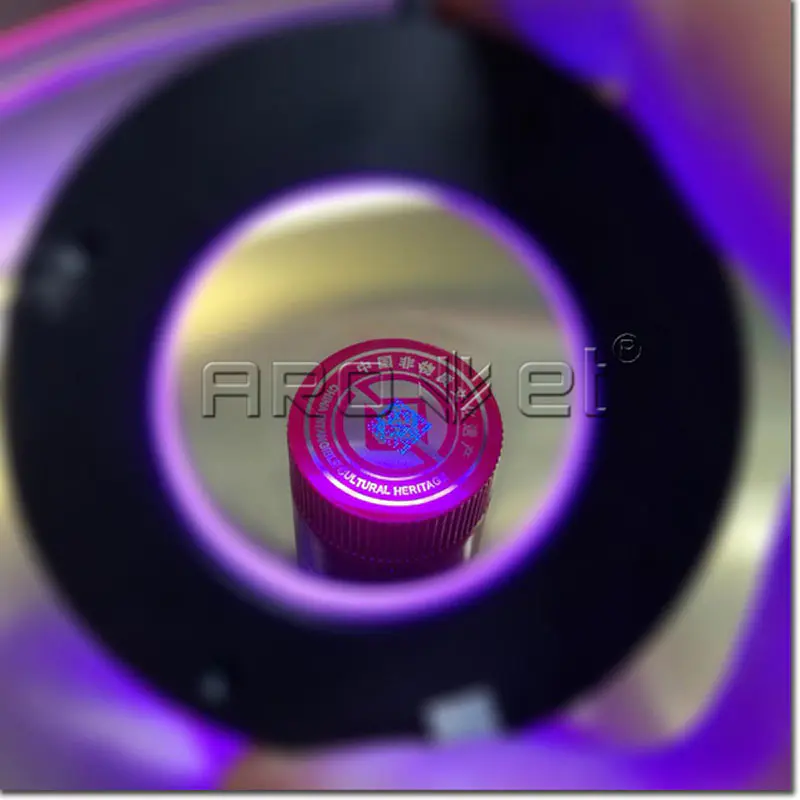

Bottle caps have the ability to protect the airtightness of products, so they are widely used in bottled products. Therefore, bottle caps are upstream industries in the food, beverage, wine, chemical, and pharmaceutical industries, and are key products for bottle container packaging. Arnoldjet inkjet printer company has more than ten years of experience, and is committed to the research and development, production and sales of variable data inkjet printers. The coding equipment can print variable QR codes and other on various bottles and caps. Content, bottle caps are indispensable not only in food or industrial applications. Fortunately, there are plastic bottle cap inkjet printers to cooperate with merchants to solve the problem of anti-counterfeiting traceability coding, and use high-quality coding equipment to help you. The low-cost and efficient plastic bottle cap inkjet printer has a QR code identification application on the top of the bottle cap. The two common types of two-dimensional codes are QR code and DM code. Dimension code, automatic generation of serial number, including production site, specifications, batch, production date, time, shift and other information, at the same time through specific coding rules, can play a role in anti-counterfeiting; in addition, jump to the relevant web site, query For activities such as authenticity or lottery, red envelopes, etc., the series of actions of scanning codes facilitates manufacturers to collect data and analyze. The plastic bottle cap inkjet printer with stable ink supply adopts a negative pressure ink supply system and positive pressure nozzle cleaning, which ensures the stability and reliability of the ink system and its service life. UV inkjet is a new technology, and commodity bottle cap inkjet printers are available. The convenience of inkjet technology has the advantage of curing adhesion. The platform can be combined online to achieve linkage and personalized customization. The inkjet system has accurate material positioning, with an error of plus or minus 0.5mm, and stable inkjet printing quality. It is a complete set of solutions for coding and tailoring for the cap making industry.

Custom message

Related Products

arojet@arojet.com

arojet@arojet.com