The Role of Industrial Inkjet Printers in Pharmaceutical Labeling

The pharmaceutical industry is one of the most regulated industries in the world, and labeling requirements are some of the most stringent. From storage conditions to dosage information, pharmaceutical labels need to be precise, clear, and consistent to ensure patient safety. In recent years, industrial inkjet printers have become an integral part of the pharmaceutical labeling process, providing manufacturers with a fast, cost-effective, and reliable way to produce high-quality labels that meet regulatory requirements.

1. Introduction to industrial inkjet printers

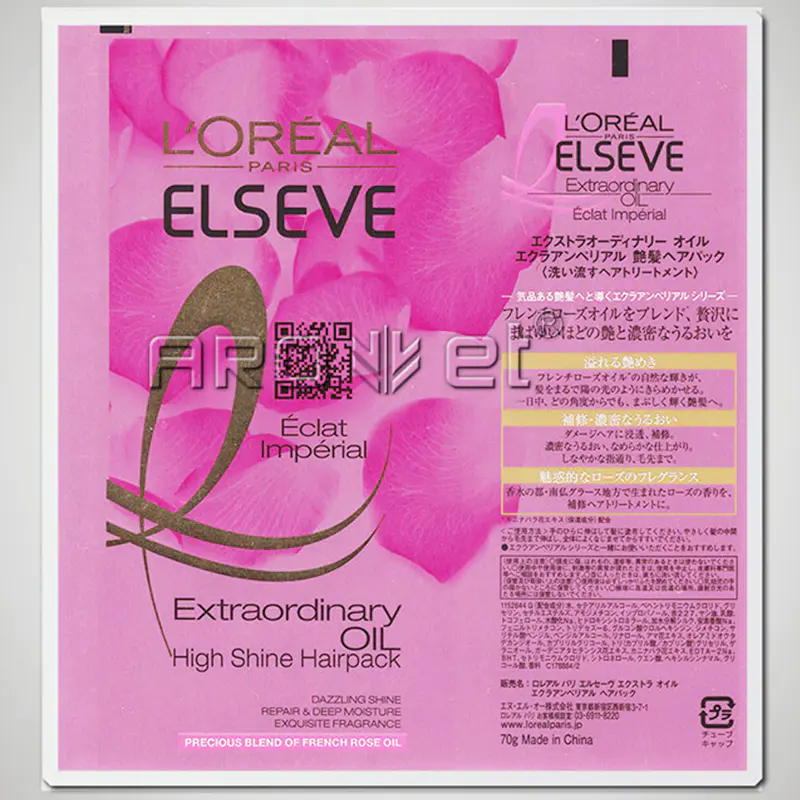

Industrial inkjet printers are a type of digital printing technology that uses ink droplets to form images or text on a substrate. Inkjet printers are widely used in a range of industries for printing on a variety of materials, including paper, plastic, metal, and glass. In pharmaceutical labeling, industrial inkjet printers are used to print high-resolution product information, including ingredient lists, dosage information, and storage instructions.

2. Benefits of using industrial inkjet printers in pharmaceutical labeling

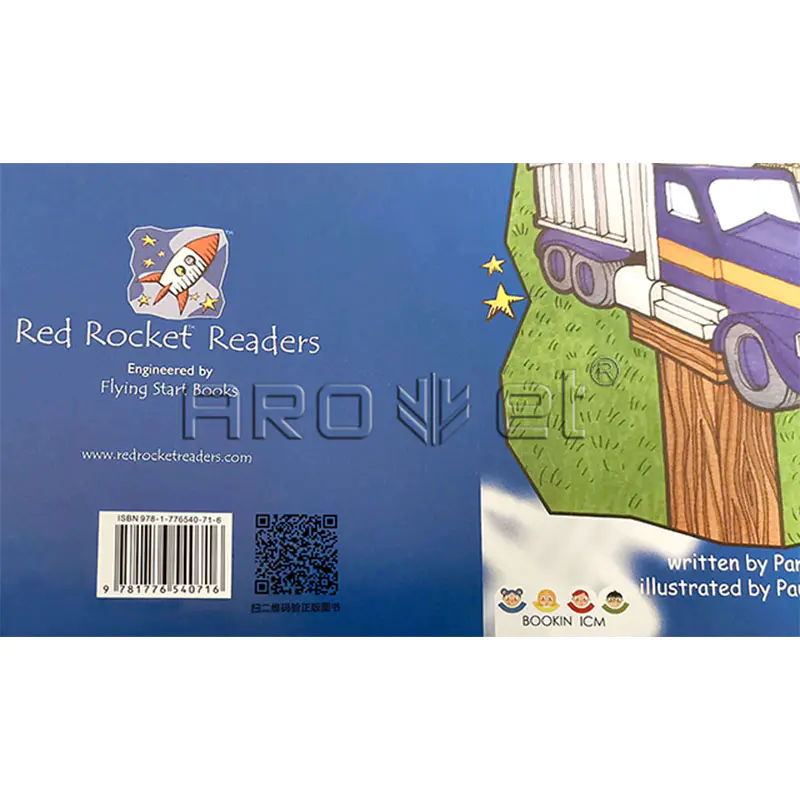

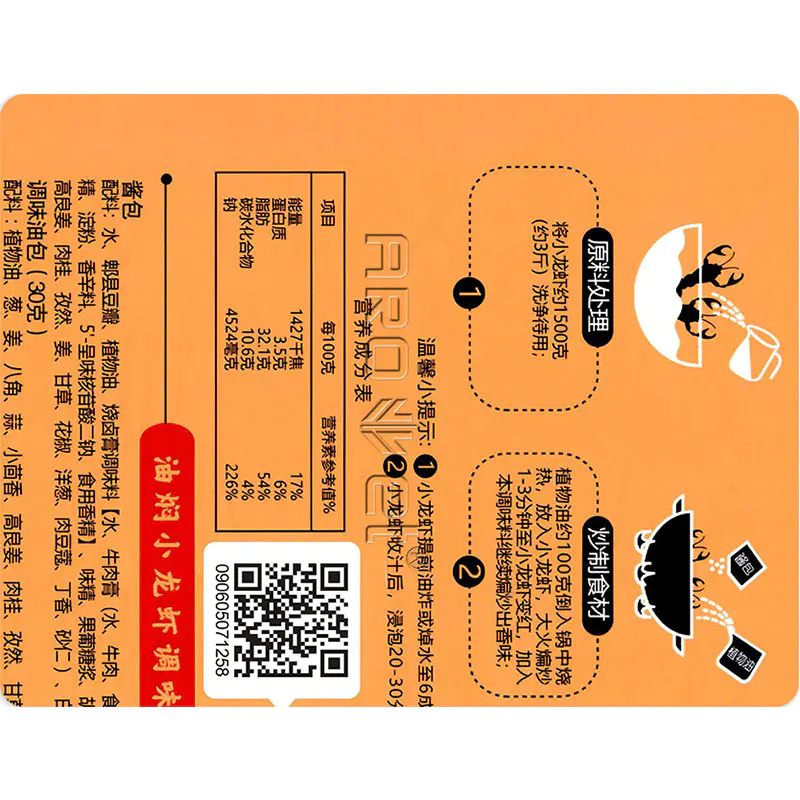

One of the main benefits of using industrial inkjet printers in pharmaceutical labeling is the ability to produce high-quality labels quickly and efficiently. Industrial inkjet printers can print at a very high resolution, allowing for crisp text and images, even on small labels. Inkjet printers also offer the flexibility to print variable data, such as lot numbers and expiration dates, which can be crucial in the pharmaceutical industry.

Another benefit of using industrial inkjet printers in pharmaceutical labeling is the cost savings they offer. Inkjet printers require less floor space and energy than traditional printing methods, such as offset printing, and they have lower start-up costs, making them ideal for small to medium-sized runs.

3. Challenges of using industrial inkjet printers in pharmaceutical labeling

While industrial inkjet printers offer many benefits, there are some challenges to using them in pharmaceutical labeling. One of the main challenges is ensuring regulatory compliance. Pharmaceutical labels are subject to strict regulations governing everything from font size to the placement of warnings and disclaimers. Industrial inkjet printers must be capable of producing labels that meet these regulatory requirements, and manufacturers must ensure that they are properly validated before they can be used.

Another challenge is ink selection. Pharmaceutical labels must be resistant to abrasion, water, and other conditions that could cause them to smear or fade. Industrial inkjet printers use different types of ink, and manufacturers must choose the ink that will provide the necessary durability, while also ensuring that the ink does not interfere with the product's quality, safety, or efficacy.

4. Inkjet printer technologies used in pharmaceutical labeling

There are several inkjet printer technologies used in pharmaceutical labeling, including thermal inkjet (TIJ), piezo inkjet, and continuous inkjet (CIJ).

Thermal inkjet printers use a thermal printhead to heat ink, which then forms droplets that are propelled onto the substrate. TIJ printers are known for their high resolution and fast printing speeds and are ideal for printing small, high-resolution images and text.

Piezo inkjet printers use a piezoelectric element to create droplets of ink that are ejected onto the substrate. Piezo inkjet printers offer greater flexibility in terms of ink selection and are ideal for printing on a variety of substrates, including paper, plastic, and metal.

Continuous inkjet printers use a continuous stream of ink droplets that are selectively charged and deflected onto the substrate. CIJ printers are known for their reliability and flexibility in terms of ink selection and are ideal for printing high-speed, high-volume runs.

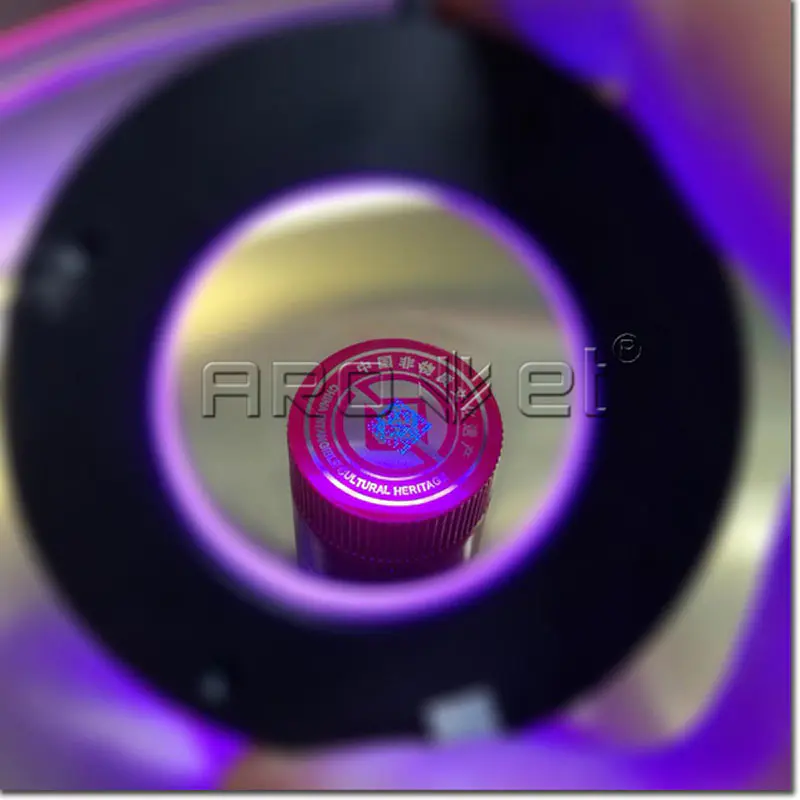

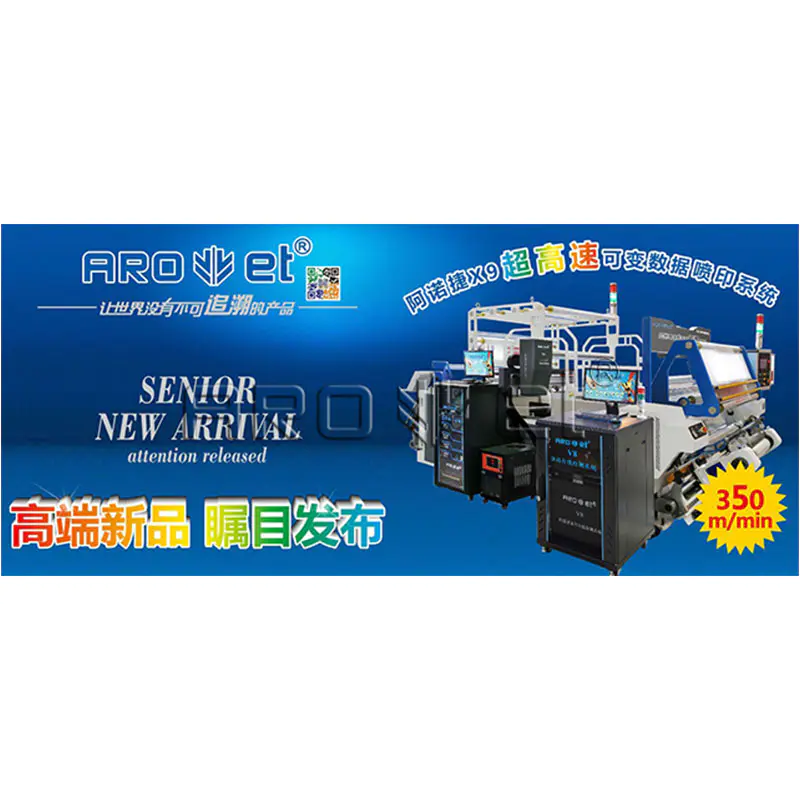

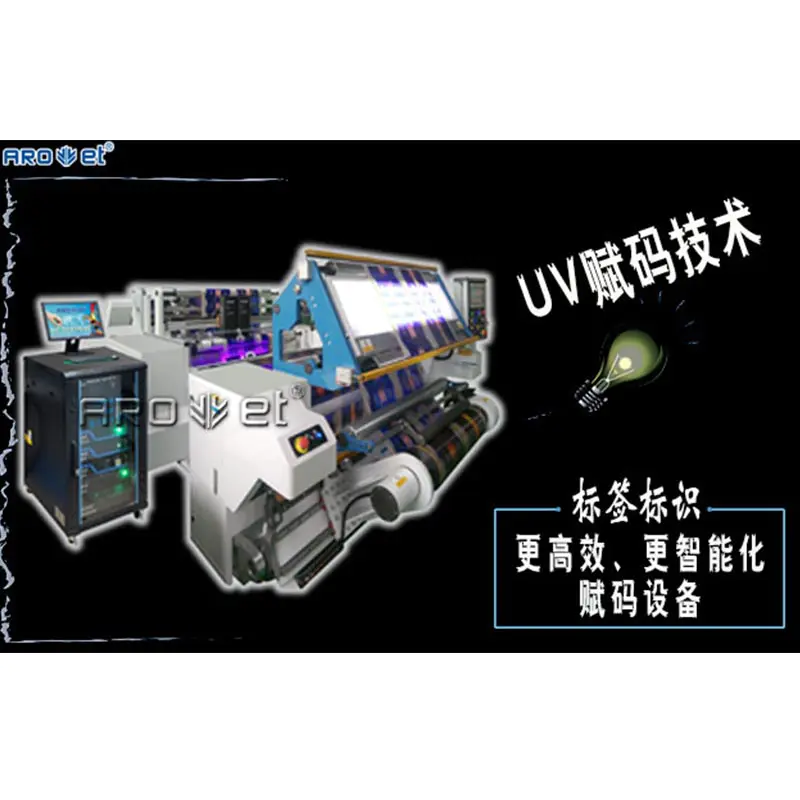

5. Advancements in industrial inkjet printer technology

Advancements in industrial inkjet printer technology have made them even more attractive to pharmaceutical manufacturers. Some of the latest advancements include increased resolution, faster printing speeds, and improved ink durability. Manufacturers are also developing new inks that are resistant to more extreme conditions, such as high temperatures and humidity.

Conclusion:

Industrial inkjet printers have become an integral part of pharmaceutical labeling, offering manufacturers a fast, cost-effective, and reliable way to produce high-quality labels that meet regulatory requirements. While there are challenges to using industrial inkjet printers in pharmaceutical labeling, advancements in technology are making them even more attractive to manufacturers. With their high resolution, fast printing speeds, and ability to print variable data, industrial inkjet printers are helping to streamline the labeling process and ensure patient safety.

As a entrepreneur, being trapped in a company under multiple quality problems never appealed to Guangdong AROJET Ink Jet Technology Co., Ltd..

Review Guangdong AROJET Ink Jet Technology Co., Ltd.'s progress at regular intervals, so we can continue with the strategies that work well and change or eliminate the ones that don't give the results we are looking for.

We want to be careful and deliberate about developing Arojet, from the platform we choose, to the way we approach it, to the methods we use.

Guangdong AROJET Ink Jet Technology Co., Ltd. knows how important it is to offer optional extras, such as industrial inkjet printerinkjet printer manufacturers to provide quality products for customers.

arojet@arojet.com

arojet@arojet.com