Printing on Non-Traditional Surfaces with Single Pass UV Printers

Printing on Non-Traditional Surfaces with Single Pass UV Printers

Printing on traditional surfaces such as paper, plastic, and fabric is now becoming outdated. With the advancement of technology, there has been an increased demand for printing on surfaces that were previously deemed non-printable. Printing on non-traditional surfaces like wood, metal, glass, and ceramics, for instance, require specialized printing equipment for high-quality, scratch-resistant, and long-lasting prints. One of the latest printing technologies that come to mind when printing on non-traditional surfaces is single-pass UV printers. These printers are best suited for industrial applications that require fast printing speeds and efficient ink drying. This article delves into how single-pass UV printers work and the various surfaces they can print on.

How single-pass UV printers work

Single-pass UV printers are so-called because they complete a single pass on the substrate they are printing on, depositing CMYK or white ink droplets precisely where needed. The ink droplets are instantly dried or cured by UV lamps, creating a hard and durable print on a wide range of surfaces. One of the advantages of single-pass printing compared to traditional printing methods like screen printing is its ability to modify designs on the fly. With single-pass UV printing, printing plates or screens do not need to be changed to modify an image, as the image can be readily edited on the computer before printing. Moreover, unlike traditional printing, single-pass UV printing does not require long ink drying times, resulting in shorter production times.

Various surfaces that single-pass UV printers can print on

Single-pass UV printers' versatility lies in their exceptional ability to print on a wide range of surfaces such as wood, metal, glass, leather, and ceramics. These surfaces have unique properties that make printing on them using traditional methods challenging, and single-pass UV printers offer a solution to overcome these challenges.

1. Printing on Wood Surfaces

Printing on wood is a relatively new surface application that is now becoming a popular art form. One of the common applications of printing on wood is personalized signs that can be used in interior design, housewarming gifts, or outdoor use. Traditional printing on wood surfaces requires screen printing, which can be time-consuming and costly. Single-pass UV printers offer a hassle-free solution to print on various wood types, including hardwood, plywood, MDF, particleboard, and engineered wood. Moreover, UV printers can produce high-quality, durable prints on wood surfaces with exceptional resolution and bright colors, even on rough or textured surfaces.

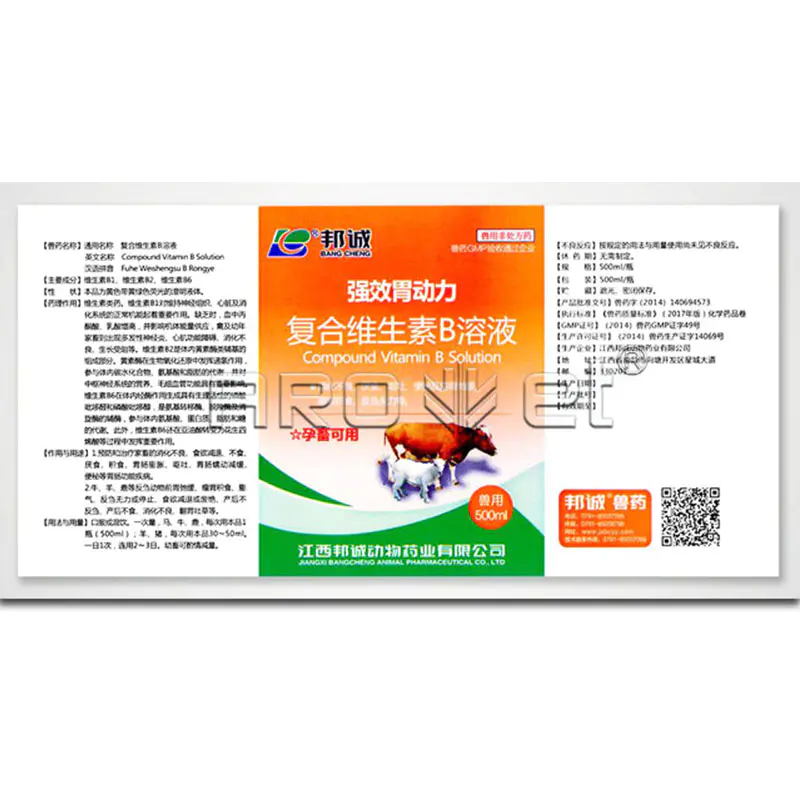

2. Printing on Metal Surfaces

Printing on metal surfaces is crucial in industrial applications as metal parts and products require clear and detailed marking for inventory or traceability purposes. Conventional marking methods like engraving or etching can be costly, time-consuming, or wear out over time. Single-pass UV printers offer a cost-effective and efficient solution to print on various metal surfaces such as aluminum, brass, copper, and stainless steel. UV printers can print high-quality, permanent marks at fast speeds without the need for pre-treatment or additives.

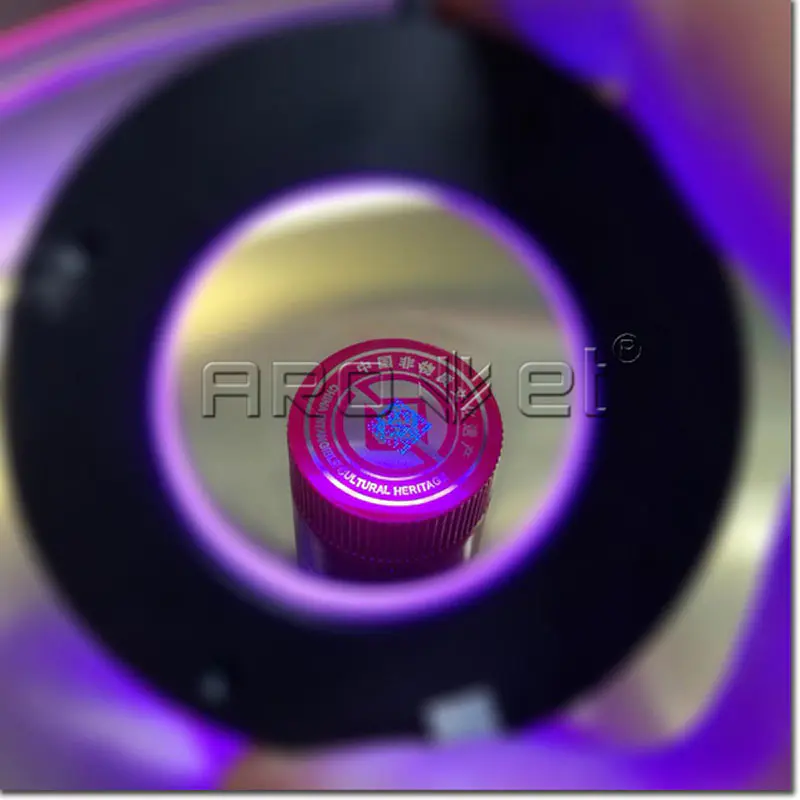

3. Printing on Glass Surfaces

Printing on glass is a popular application in the promotional and branding market, where eyewear, drinkware, and other glassware require branding or logo engraving. Traditional printing methods like pad printing, etching, and engraving can be time-consuming, costly, or unsuitable for printing small detailed images. Single-pass UV printers offer a faster and cost-effective solution to print on various glass surfaces size without the need for pre-treatments. The prints result in sharp and clear images with bright colors and excellent adhesion.

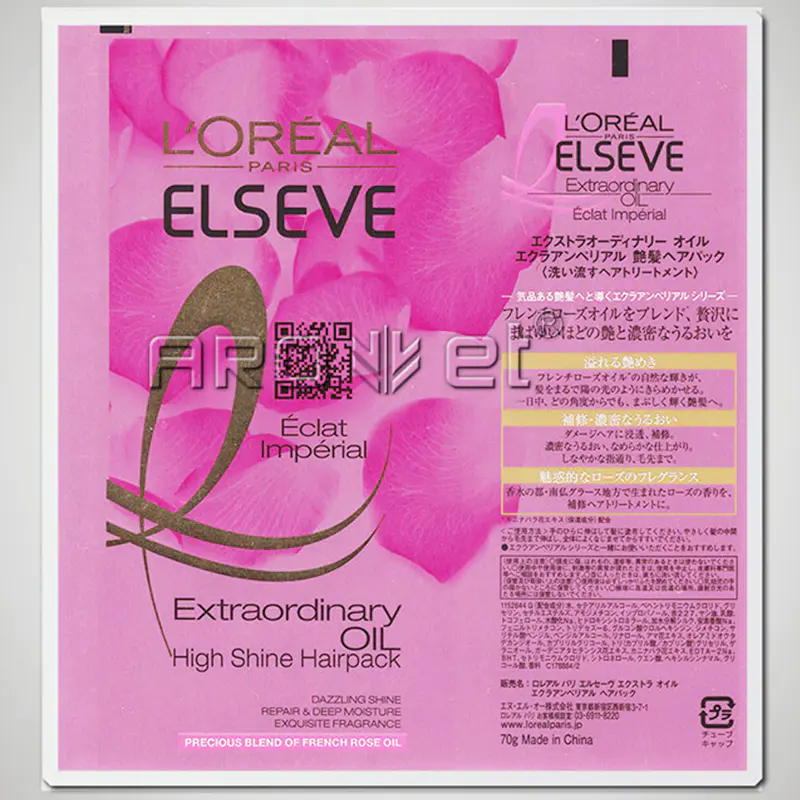

4. Printing on Leather Surfaces

Printing on leather surfaces is crucial in creating personalized or branded leather goods like wallets, belts, bags, or accessories. Traditional printing on leather requires heat transfer or screen printing, which can be expensive or limited in design freedom. Single-pass UV printers offer a highly efficient and flexible solution to print on various leather types with bright colors, sharp details, and excellent adhesion. UV printers can print on both smooth and textured leather surfaces without sacrificing quality.

5. Printing on Ceramic Surfaces

Printing on ceramic surfaces is a popular application in the interior design, art, and gift markets, where customized ceramic tiles, mugs, or vases are highly demanded. Traditional ceramic printing methods like screen printing, transfer printing, or lithography can be time-consuming or limited in printing on curved or bulky surfaces. Single-pass UV printers offer a high-speed and efficient solution to print on various ceramic surfaces with exceptional resolution, bright colors, and sharp details. UV printers can print on both glazed and unglazed ceramic surfaces, resulting in scratch and fade-resistant prints.

In conclusion, single-pass UV printers offer efficient and flexible solutions in printing on various non-traditional surfaces like wood, metal, glass, leather, and ceramics. These printers offer high-quality, permanent, and scratch-resistant prints at high speeds, resulting in cost-effective and versatile printing solutions. As more applications demand printing on unusual surfaces, single-pass UV printers are poised to offer solutions that cater to these demands.

arojet@arojet.com

arojet@arojet.com