Different Inkjet Inks Used for Single Pass UV Printing Applications

Different Inkjet Inks Used for Single Pass UV Printing Applications

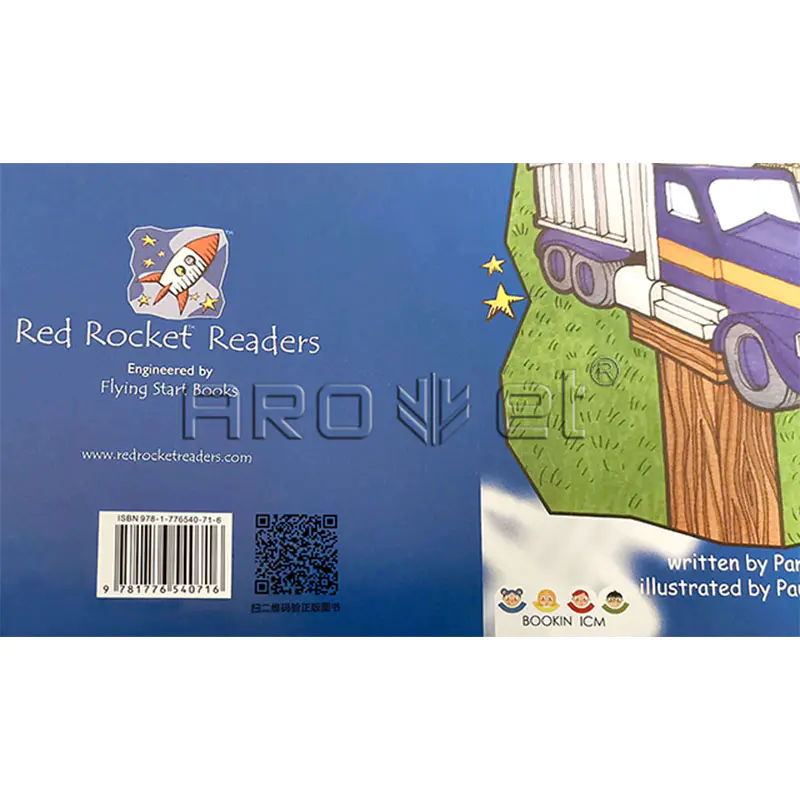

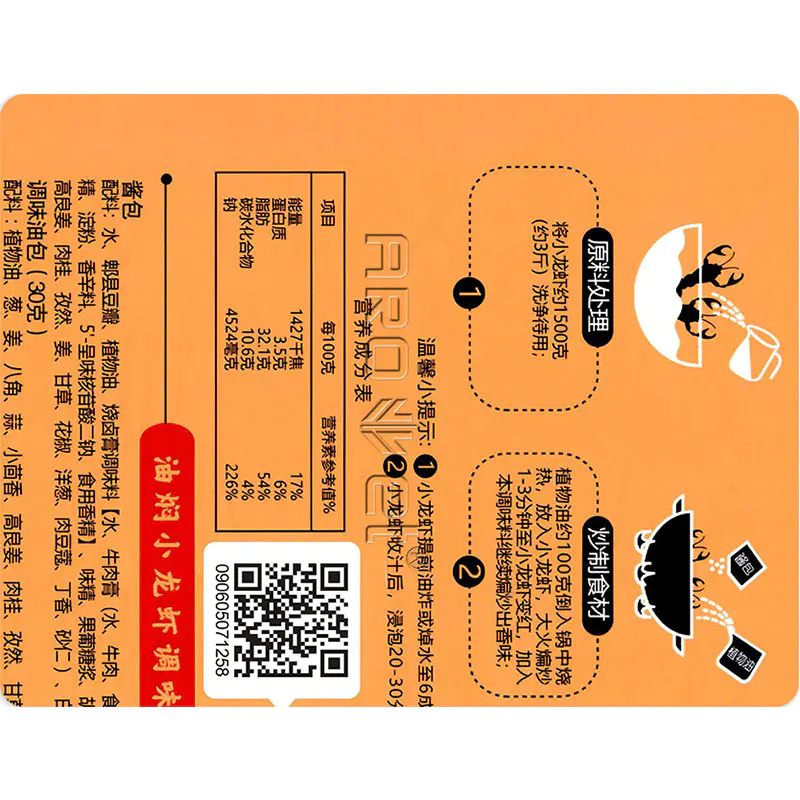

Inkjet printing has come a long way since it was first introduced in the early 1980s. Traditional inkjet printing broadly involves spraying droplets of liquid ink onto a substrate to create a printed image. Inkjet printing has been successfully used in many applications, including graphic design, textiles, and packaging. Among the technologies used in inkjet printing is a UV curing inkjet printer, which is particularly suited for single pass printing applications.

This article examines the different types of inkjet inks available for single pass UV printing applications. This emerging technology has significant advantages in terms of speed, accuracy, and resolution. It is ideal for printing on a variety of substrates, including paper, plastic, metal, and ceramics.

Substrate Compatibility for Single Pass UV Printing

Single pass UV inkjet printing is suitable for printing on a wide variety of substrates, including paper, plastic, glass, ceramics, and metal. The ink must be able to adhere to the substrate, dry quickly, and maintain its color intensity. This is where different types of inks come into play.

Inkjet inks are formulated for specific types of substrates, and selecting the right ink for a particular application is critical for achieving high-quality, long-lasting prints. In this section, we will look at various types of inks and their applications.

Dye-Based Inks

Dye-based inks contain colored dyes dissolved in a liquid that evaporates when printed, leaving behind the color pigment on the substrate. This type of ink is suitable for printing on porous surfaces, such as paper. The advantage of dye-based inks is that they produce vivid, bright colors with high color accuracy and sharpness.

However, dye-based inks are not suitable for printing on non-porous surfaces, such as plastic and metal. They tend to bleed and fade over time, especially when exposed to light and air. Therefore, dye-based inks are not recommended for applications that require long-term durability.

Pigment-Based Inks

Pigment-based inks contain solid pigments that are suspended in a liquid carrier that dries quickly on the substrate. This type of ink is suitable for printing on both porous and non-porous surfaces, such as textiles, plastics, and metals.

Pigment-based inks provide better durability and resistance to fading than dye-based inks. They are also water-resistant, making them ideal for printing applications that require exposure to moisture and water.

UV-Curable Inks

UV-curable inks are specifically designed for single-pass UV printing applications. These inks contain special photo initiators that convert the liquid ink into a solid on exposure to UV light. This process is known as UV-curing, which is fast and produces high-quality, durable prints that are resistant to fading and scratching.

UV-curable inks are ideal for printing on a wide range of substrates, including plastics, metals, glass, and ceramics. They produce vibrant colors with high color accuracy and sharpness. They are also eco-friendly, as they do not emit volatile organic compounds (VOCs) during the printing process.

Solvent Inks

Solvent inks contain pigments or dyes that are dissolved in a liquid solvent that evaporates during printing, leaving behind the color pigment on the substrate. Solvent inks are suitable for printing on plastic and vinyl substrates.

The advantage of solvent inks is that they produce vibrant, durable colors that are resistant to fading and scratching. They are also water-resistant, making them ideal for printing applications that require exposure to moisture and water. However, solvent inks emit harmful VOCs during the printing process, which can cause health and environmental issues.

Conclusion

Single pass UV printing is an emerging technology with significant advantages over traditional printing methods. The key to achieving high-quality, durable prints in single pass UV printing applications is selecting the right ink for the substrate.

Dye-based inks are suitable for printing on porous surfaces such as paper, while pigment-based inks are suitable for printing on non-porous surfaces such as plastics and metals. UV-curable inks are specifically designed for UV-curing and provide high-quality, durable prints on a wide range of substrates.

Solvent inks are suitable for printing on plastic and vinyl substrates but emit harmful VOCs during the printing process. Therefore, selecting the right ink for a single pass UV printing application is essential for achieving long-lasting, high-quality prints.

arojet@arojet.com

arojet@arojet.com