Reducing Costs and Enhancing Productivity with Industrial Inkjet Printers

Reducing Costs and Enhancing Productivity with Industrial Inkjet Printers

Industrial inkjet printers have taken the manufacturing industry by storm. They have replaced the traditional printing methods such as screen printing, label printing, and pad printing. Inkjet printers offer more versatility and quality at a lower cost, making them a popular choice for many manufacturers.

In this article, we discuss how industrial inkjet printers reduce costs and enhance productivity for manufacturers by exploring five key areas:

1. Cost savings

2. Increased printing speed

3. Versatility

4. Improved quality

5. Reduced errors

Cost Savings

Industrial inkjet printers have revolutionized the printing industry by reducing costs. They require less maintenance and have lower operational costs than traditional printing methods. Industrial inkjet printers do not require printing plates or screens, which means there is no need for additional equipment, chemicals, or materials. This significantly reduces the manufacturing cost and time spent on the printing process.

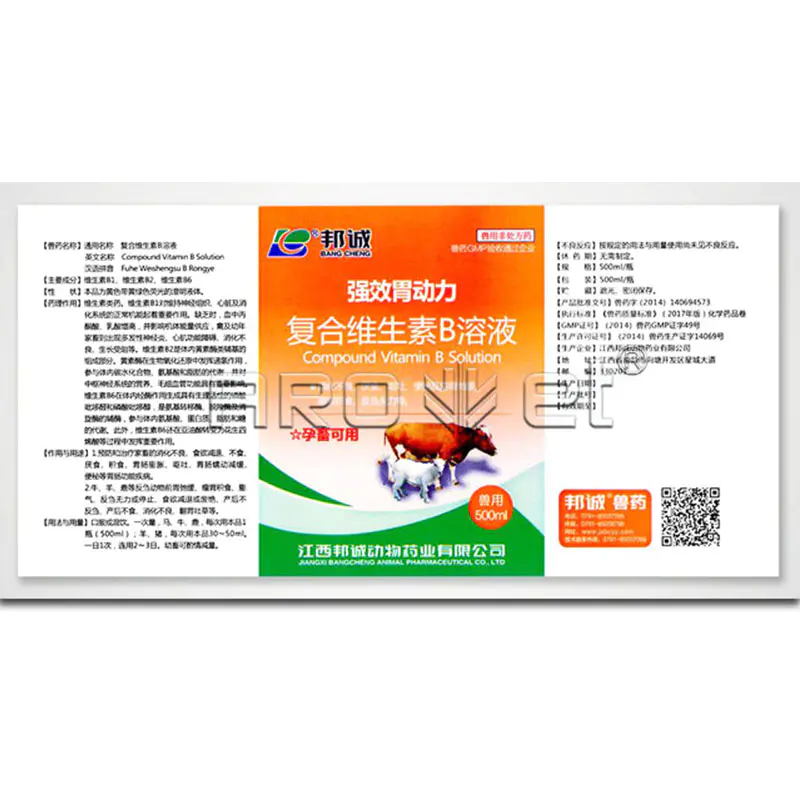

Moreover, the inkjet technology allows manufacturers to print on a range of surfaces, including plastic, metal, and glass. This eliminates the need to buy specialized materials, reducing the production cost even further. As a result, manufacturers can use the saved cost for other parts of the production process or invest in better equipment for their facility.

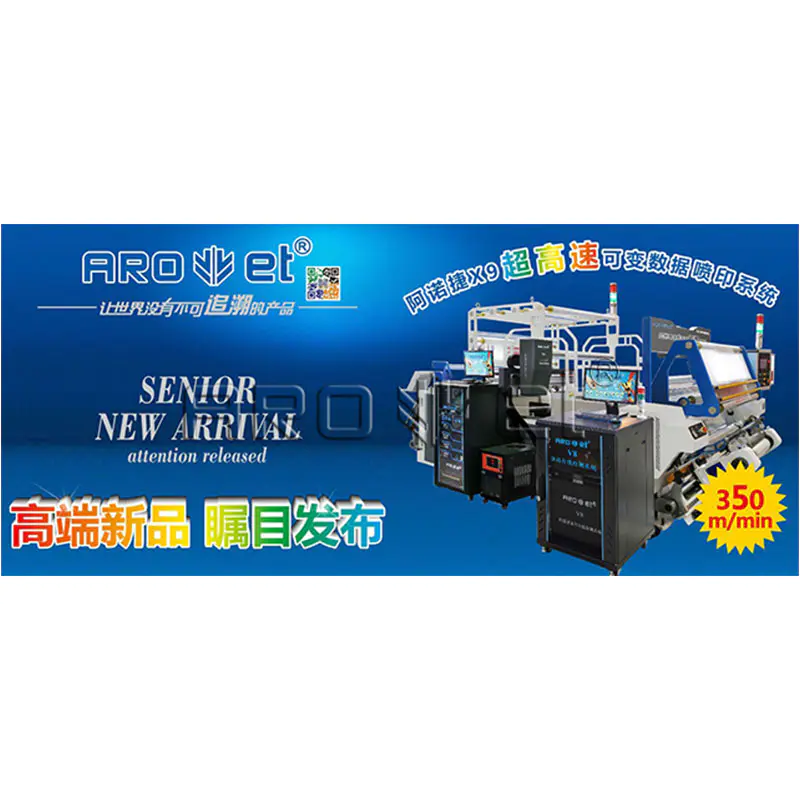

Increased Printing Speed

Another advantage of industrial inkjet printers is their speed. They can print a large volume of products within a short period. Inkjet printers have a high printing resolution and can print multiple designs on the same surface without any loss of quality. Moreover, they can print products in full color, eliminating the need for separate printing passes. This results in faster production and reduces the time required for printing.

The increase in the printing speed means manufacturers can produce more products within a shorter time frame, allowing them to keep up with customer demand and decrease the time to market for their products.

Versatility

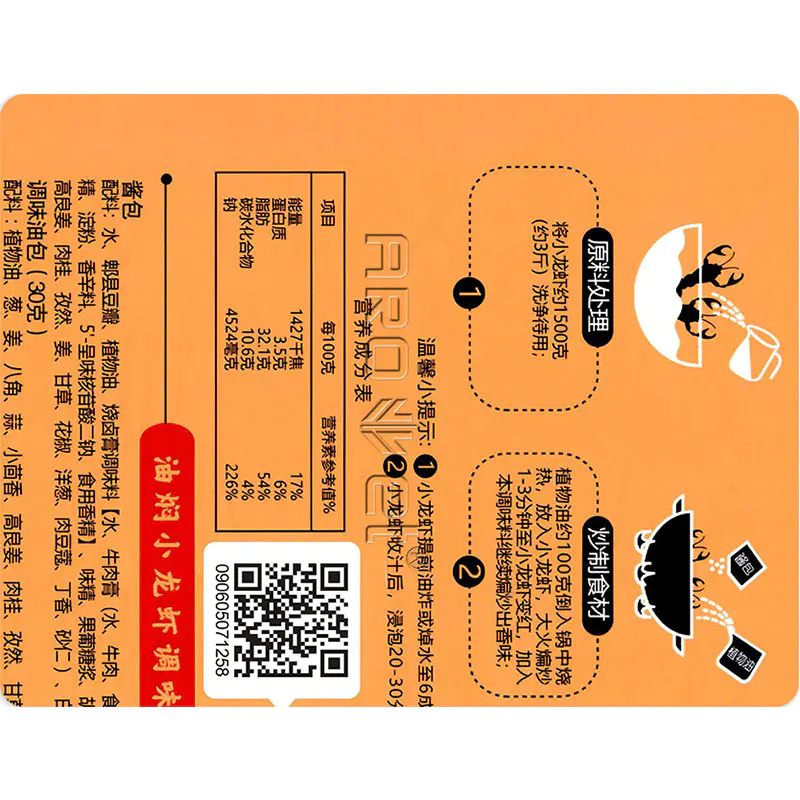

Industrial inkjet printers offer superior versatility over other printing methods. They can print on a variety of surfaces, shapes, and sizes with ease. This technology allows manufacturers to produce customized products with different designs, logos, and text, without any downtime in between. The software used in the inkjet printers allows for design changes, making it easy to print different designs on the same product without the need for any additional set-up time.

This flexibility is particularly useful for manufacturers who produce a range of products with different designs. Inkjet printers allow them to print in small batches to match demand, saving time and money by reducing waste and inventory costs.

Improved Quality

Inkjet printers produce high-quality prints that are more precise and sharper than other printing methods. The ink used in inkjet printers is water-based, making it environmentally friendly and safe for use on products that will come into contact with food or other sensitive items. Moreover, the ink dries quickly, ensuring that the print does not smudge or smear during handling and transportation.

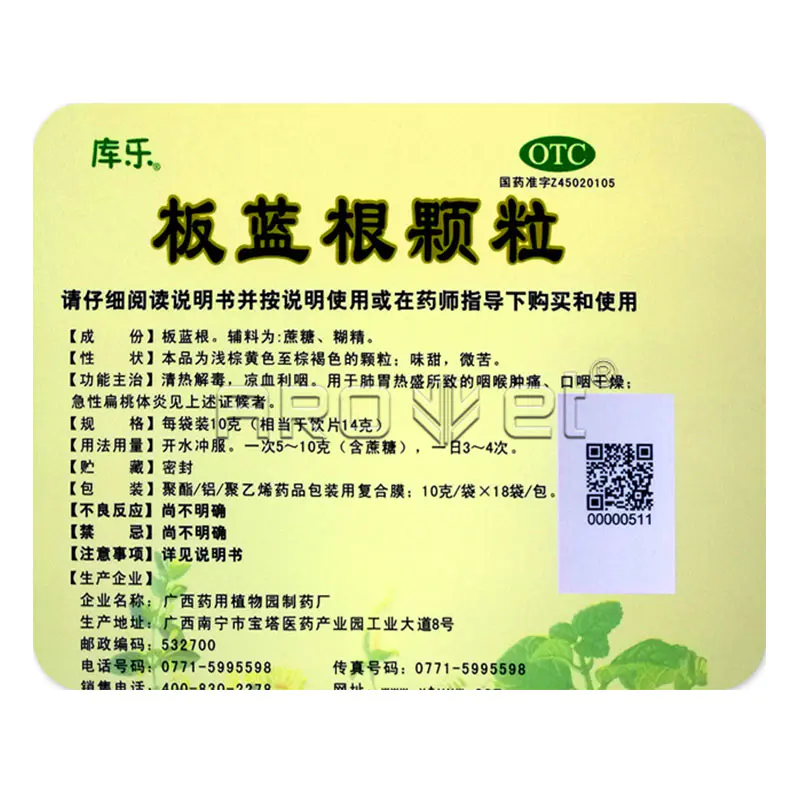

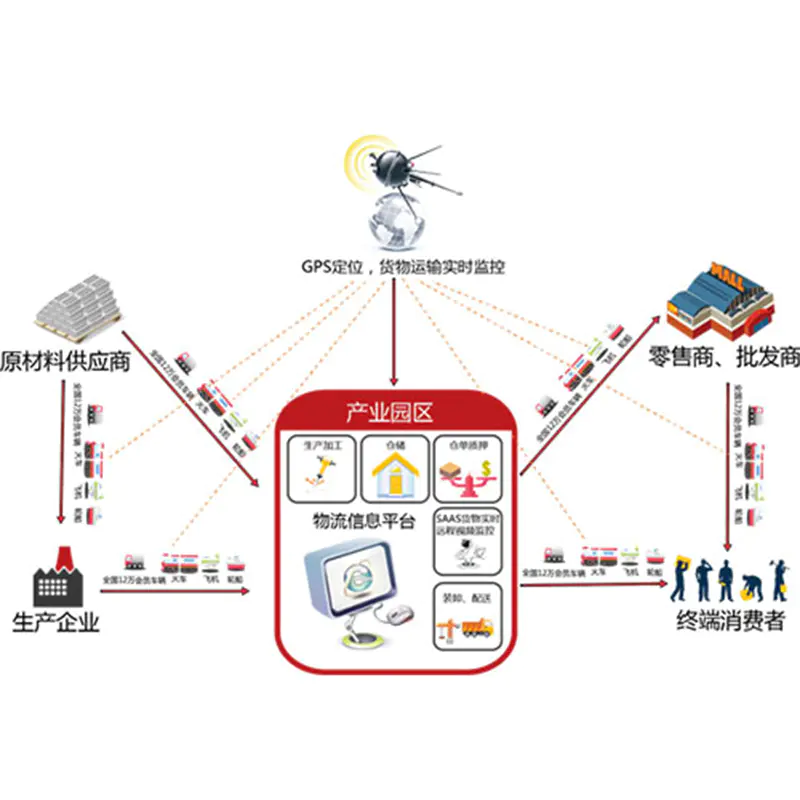

The high-resolution printing offered by inkjet printers also allows manufacturers to create clear and crisp barcodes in smaller sizes. This is essential for industries that require barcode printing for product tracking and inventory management. Barcode printing on the product ensures that the correct product is delivered and makes it easy for manufacturers to track and manage their inventory.

Reduced Errors

One of the biggest advantages of industrial inkjet printers is the reduction in errors. Traditional printing methods require manual labor and are prone to human errors such as mislabeling, misspelling, and misprinting. Inkjet printers, on the other hand, are automated and eliminate the need for any human intervention. The software used in the printer ensures that the print is accurate and consistent, eliminating errors resulting from human intervention, saving costs on printing and material waste

Conclusion

Industrial inkjet printers are an excellent investment for manufacturers looking to enhance their productivity and reduce costs. They offer an array of benefits, including cost savings, speed, versatility, quality, and error reduction. With their automated printing process, manufacturers can produce high-quality products faster and accurately, reducing the time spent on printing and helping them keep up with customer demand. By switching to inkjet printers, manufacturers can take their printing process to a new level, a level intended to promote sustainability, quality, and speed.

At a time when technology is essential for industrial inkjet printer, ensuring that it works in a symbiotic way with your human employees is key.

Guangdong AROJET Ink Jet Technology Co., Ltd. will make a healthy profit for its owners and provide a rewarding work environment for its employees.

Guangdong AROJET Ink Jet Technology Co., Ltd. is the best manufacturer which has rich experience on manufacturing.

arojet@arojet.com

arojet@arojet.com