Printing on Demand: The Benefits of Inkjet Marking Machines

Printing on Demand: The Benefits of Inkjet Marking Machines

Printing on demand has become a crucial aspect of modern-day businesses. Many companies now operate on an efficient and timely production schedule. With the rapid progression of technology, the need for effective printing machines that can meet this production demand has never been greater. One such solution is the inkjet marking machine. In this article, we'll explore the numerous benefits of inkjet marking machines, their usage, and their advantages over traditional marking techniques.

What are Inkjet Marking Machines?

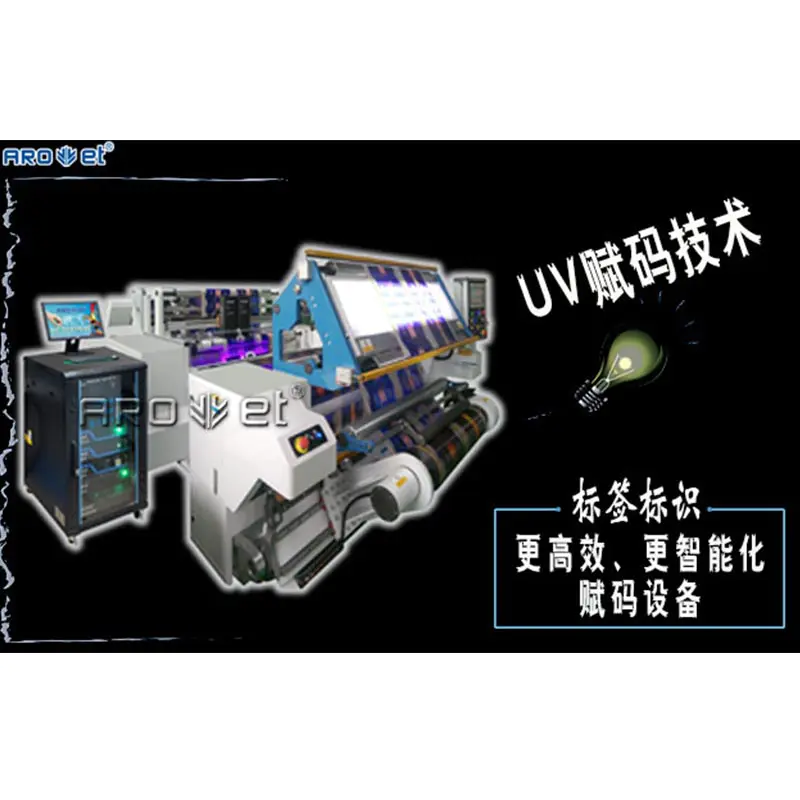

Inkjet marking machines use inkjet technology to produce high-quality prints onto various materials. They are highly versatile and can print onto practically anything - from paper, plastic, metal, glass, and more. Furthermore, these machines can print on both porous and non-porous materials, making them a valuable investment for any business producing a diverse range of products.

How Do Inkjet Marking Machines Work?

Inkjet marking machines operate by streaming ink through tiny nozzles onto a substrate or material. The nozzles are coordinated and controlled by a micro-electro-mechanical system (MEMS), which ensures an accurate and consistent print. There are two types of inkjet marking machines - continuous inkjet (CIJ) and drop on demand (DOD). CIJ machines use a continuous stream of ink to produce prints, while DOD machines deliver ink droplets only when required.

The Benefits of Inkjet Marking Machines

1. Cost-effective

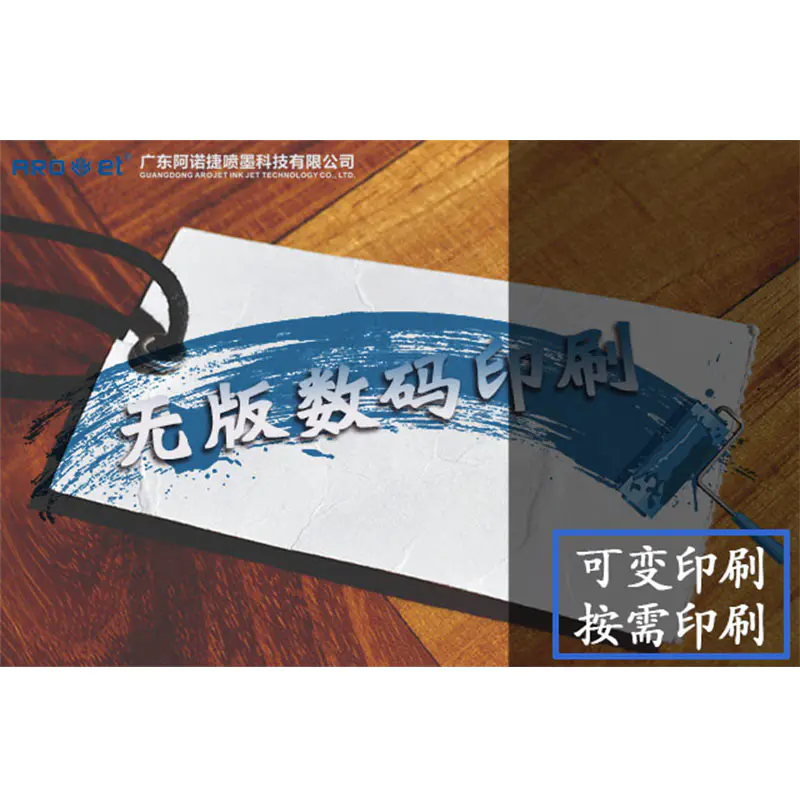

One of the most significant advantages of inkjet marking machines is that they are cost-effective. They reduce printing costs by minimizing ink usage, and because they use digital inkjet technology, there is no need for printing plates, film, or negatives. This allows for a more efficient and eco-friendly printing process.

2. Customizable Prints

With inkjet marking machines, companies have the freedom to produce customizable prints. They can adjust their designs in real-time, modify print dimensions, or make any necessary changes without incurring extra costs. This adaptability is particularly advantageous for companies that frequently alter or update their designs.

3. High-Quality Output

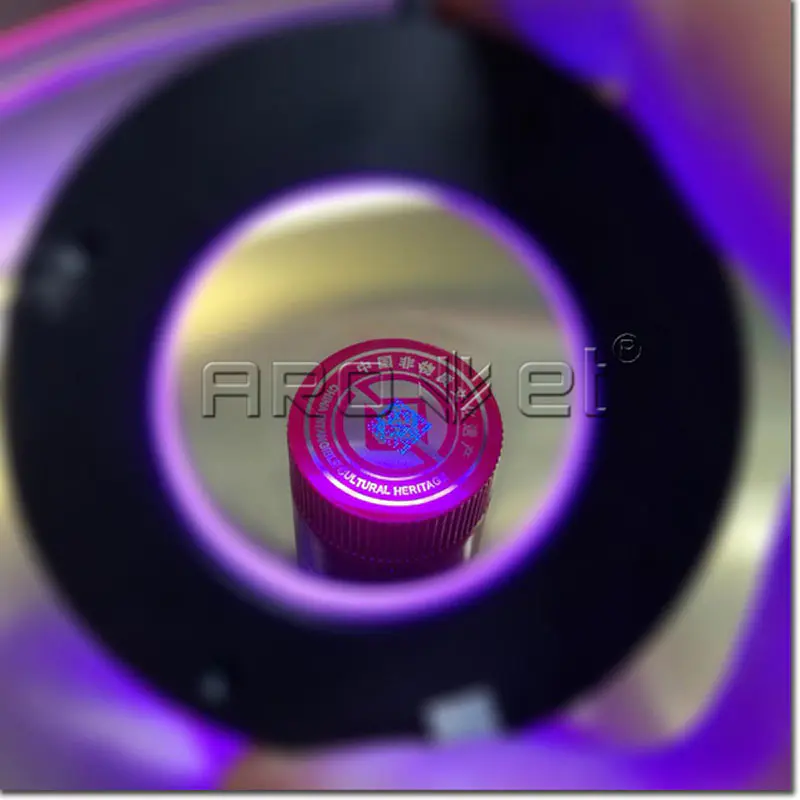

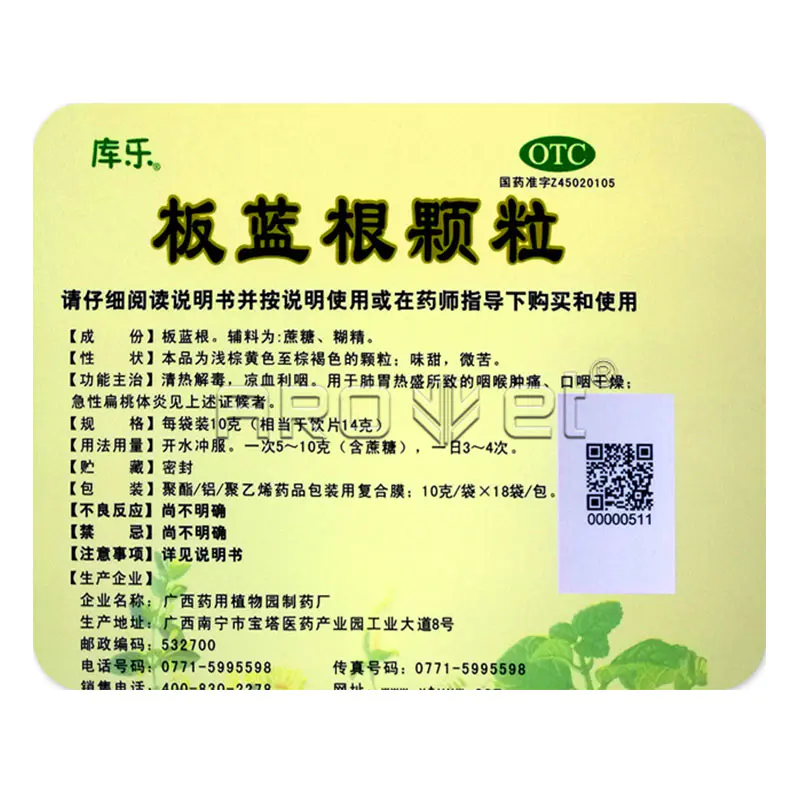

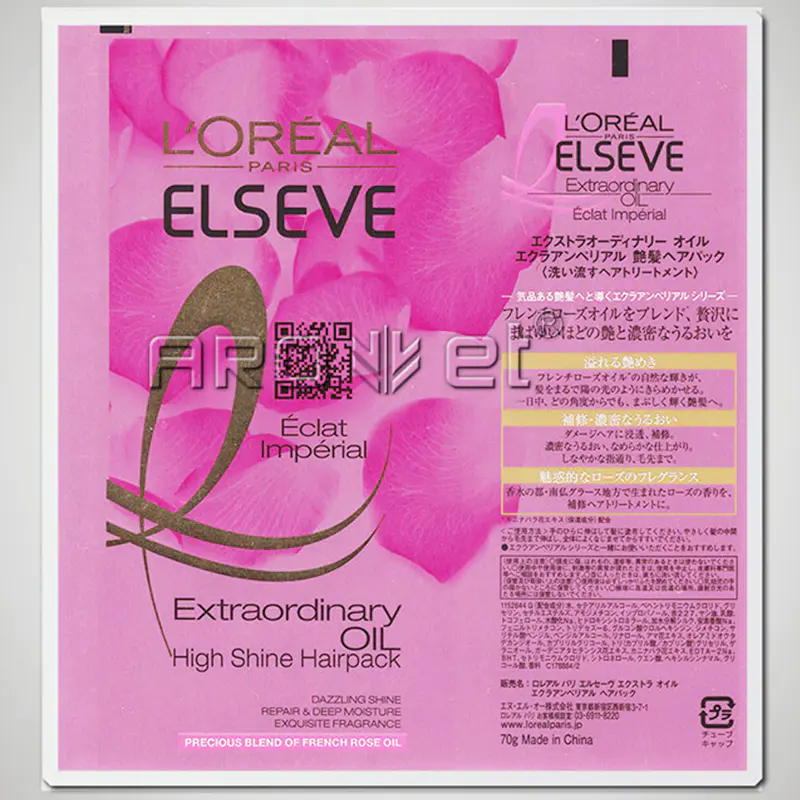

The quality of prints produced on inkjet marking machines is unmatched. The prints are intricate, sharp, and high definition. Furthermore, inkjet marking machines can print on materials with a variety of finishes, enabling complete color control, and producing photo-realistic prints. This allows for a superior and visually appealing product that is perfect for marketing and promotional materials.

4. Improved Productivity

Inkjet marking machines have significantly reduced production times for businesses. They have eliminated the need for manual laborious tasks, such as carving or etching, providing faster turnaround times. Furthermore, they have increased printing speeds, ensuring high-quality prints in a shorter amount of time.

5. Increased Versatility

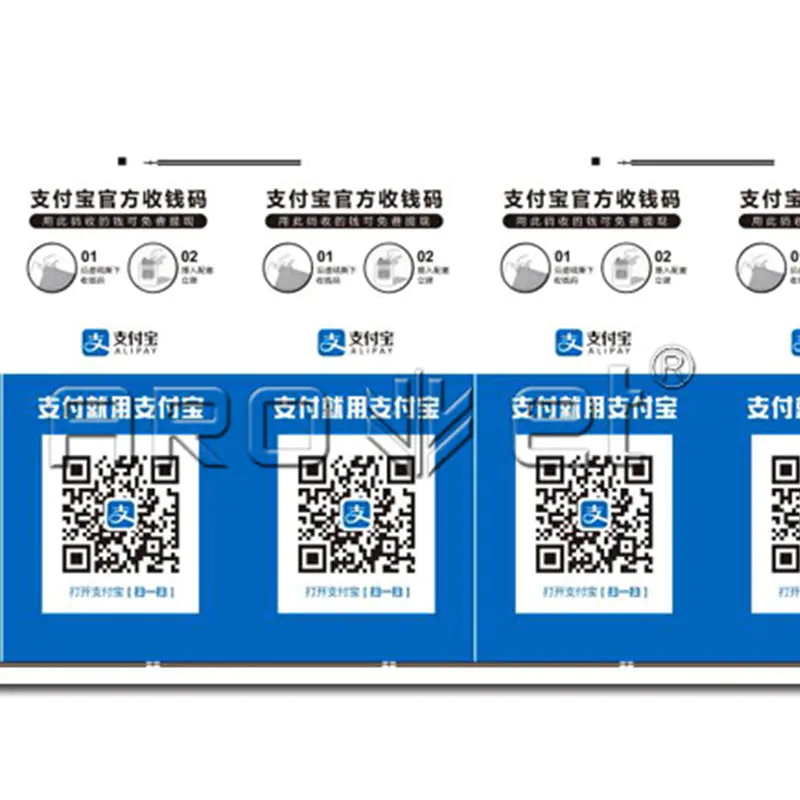

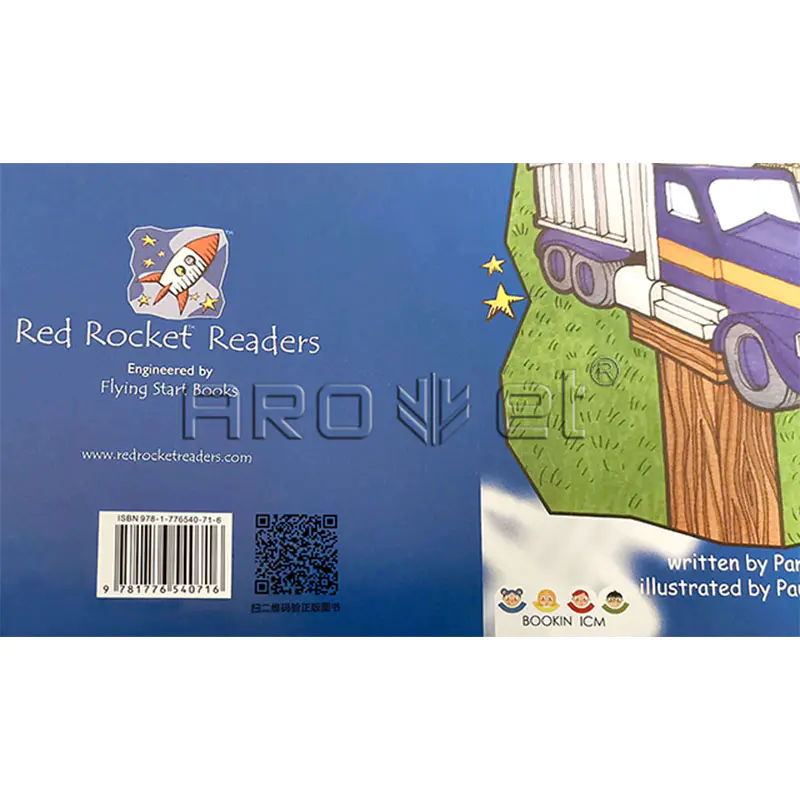

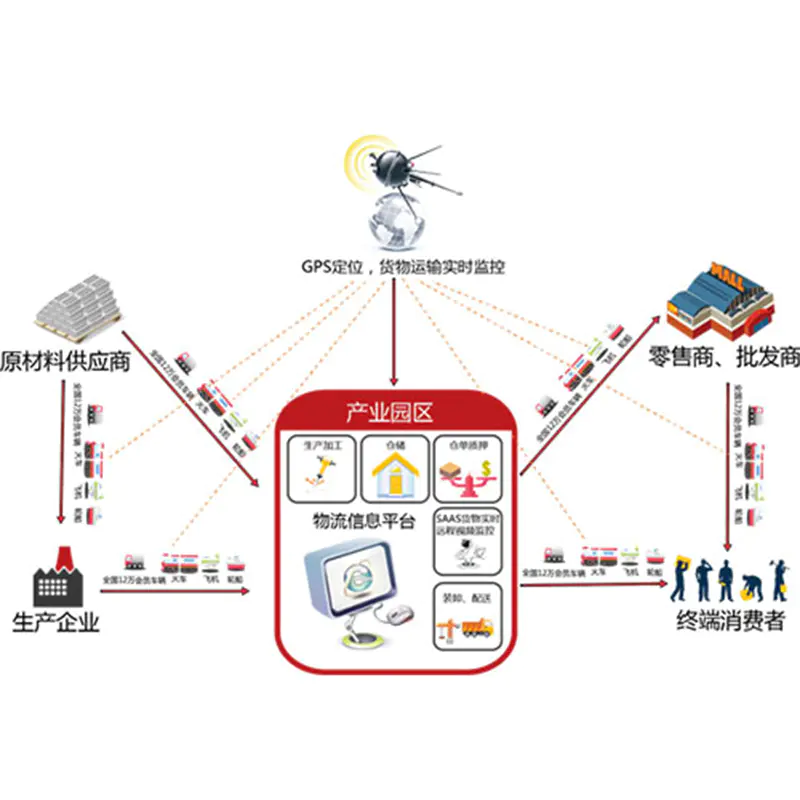

The versatility of inkjet marking machines means that they can print on virtually any surface - from paper to glass, plastic, or even metal. As such, they are suitable for a variety of printing applications, such as product labeling, barcodes, QR codes, branding, and packaging. This makes them an invaluable asset to any modern-day business, whatever their needs.

Inkjet Marking Machines versus Traditional Marking Techniques

Inkjet marking machines have numerous advantages over traditional marking techniques, such as screen printing, engraving, and offset printing. Let's explore some of these advantages.

1. Minimal Set-up Time

Traditional marking techniques require significant set-up time, including preparing screens, plates, and stencils before printing. This not only adds to production time but can also be costly. Conversely, inkjet marking machines have minimal set-up time and are ready to print instantly.

2. Consistency and Accuracy

Traditional marking techniques often produce inconsistent and inaccurate prints, as it can be challenging to control factors such as ink viscosity, temperature, and pressure. Inkjet marking machines overcome these issues by using highly accurate computer-controlled nozzles to deliver ink onto the substrate, ensuring consistent and precise printing.

3. Reduced Downtime

Traditional marking techniques often require downtime for machinery maintenance and cleaning. Inkjet marking machines require less maintenance, which reduces downtime significantly. This not only improves production efficiency but also reduces ongoing maintenance costs.

In conclusion, Inkjet marking machines offer a significant advantage over traditional marking techniques. They provide cost-effective, high-quality, customizable prints, increased productivity, versatility, and are easy to set up and maintain. As such, they are an excellent investment for any modern business looking to improve their printing capabilities, and scale their production to meet the demands of a fast-paced world.

need huge investment, so it is important to shop with caution.

Being a performance leader means Guangdong AROJET Ink Jet Technology Co., Ltd. will achieve operational excellence, industry-leading customer satisfaction and superior financial performance.

We persevere in keeping the customers pleasant and supporting them with industrial inkjet printer at a reasonable price.

First, in sparking the initial idea for a company based on manufacturing technology; and second, in designing a solution that could meet a clear market need for solving issues related to industrial inkjet printer inkjet printer manufacturers.

While manufacturing industrial inkjet printer, we always pay attention to the technology and quality of the product.

arojet@arojet.com

arojet@arojet.com