Frequently Asked Questions about Single Pass UV Printing

Frequently Asked Questions about Single Pass UV Printing

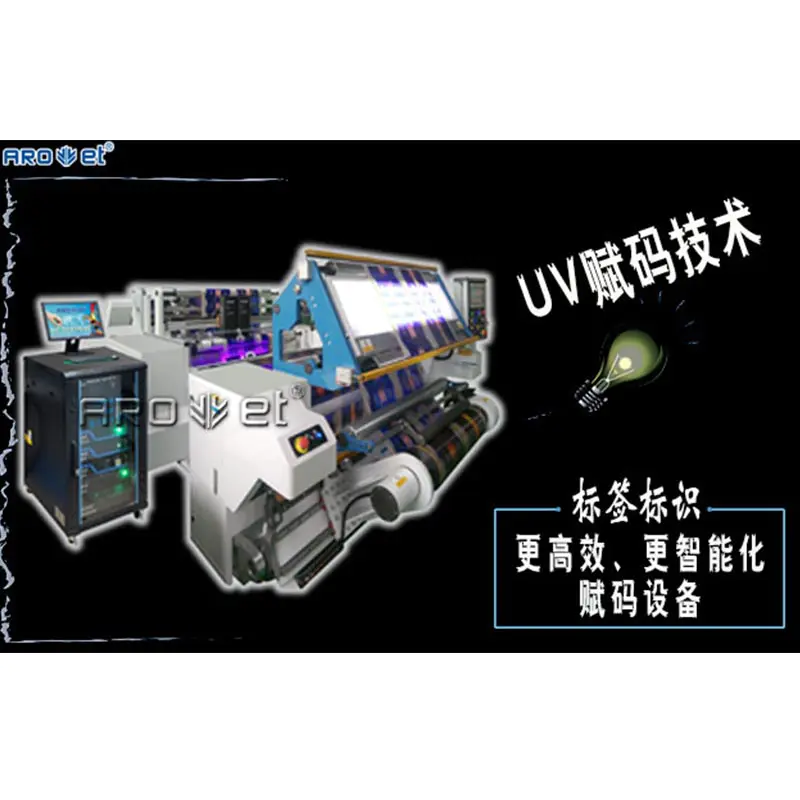

Single-pass UV printing is changing the printing industry. It is a proven technology that is changing the way businesses operate. Here are some frequently asked questions about single pass UV printing.

What is Single Pass UV Printing?

Single pass UV printing refers to a printing process that involves passing a substrate through a printer only once while using UV-curable inks to create high-quality images. The UV inks used in this process dry instantly under UV light, which eliminates the need for an additional drying process, such as heat drying. This printing method offers a range of benefits over traditional printing methods, including faster print speeds, lower ink costs, and less waste.

How Does Single Pass UV Printing Work?

In single pass UV printing, the UV-curable inks applied to the substrate are cured or dried instantly by exposure to UV light. The process happens quickly, so the print is dry and ready to use right after printing. The drying process occurs as the ink is pumped onto the substrate, and the substrate passes under the UV lamps. Because the ink never fully penetrates the substrate, it dries quickly without requiring additional heat or other drying methods.

What Are the Advantages of Single Pass UV Printing?

Single pass UV printing offers many advantages over traditional printing methods. Some of these benefits include:

- Faster print times, making it an efficient process that can handle high volumes of work.

- The ability to print on a wide range of substrates, including flexible packaging materials, non-porous surfaces, and corrugated materials.

- Lower ink costs since UV inks use less ink than traditional inks.

- Improved print quality with sharper lines, crisper colors, and better overall print quality.

- Less waste since UV inks do not seep into the substrate and dry almost instantly.

What Substrates Can be Printed With Single Pass UV Printing?

Single pass UV printing is versatile and can print on a wide range of substrates. It can print on paper, plastic, fabric, metal, wood, and many other materials. In addition, it can print on non-porous surfaces like ceramics and glass.

What Kind of Ink is Used in Single Pass UV Printing?

Single pass UV printing uses UV-curable inks, which are specially formulated to dry instantly under UV light. The inks are available in a wide range of colors, and because they dry so quickly, they can be used on a variety of substrates without smudging or bleeding. UV-curable inks also have less volatile organic compounds (VOCs), making them safer for the environment.

How Does Single Pass UV Printing Compare to Traditional Printing Methods?

Single pass UV printing offers many advantages over traditional printing methods. It offers faster print speeds, lower costs, and improved print quality. Unlike traditional printing methods, single pass UV printing does not require a drying process, which can save time and money. UV inks also have less VOCs than traditional inks, making them safer for the environment.

Conclusion

Single pass UV printing is a proven technology that is changing the printing industry. It provides fast turnaround times, lower ink costs, and improved print quality. UV-curable inks allow for printing on a wide range of substrates, including non-porous surfaces, making it a versatile technology. Finally, it is a more environmentally friendly print option than traditional printing methods. These benefits make single pass UV printing an attractive option for businesses looking to improve their print quality and efficiency.

arojet@arojet.com

arojet@arojet.com