Different Inkjet Inks Used for Industrial Printing Applications

In today's world of mass production, printing plays a vital role in ensuring that products are clearly marked and labeled. As the demand for industrial printing increases, manufacturers are seeking new ways to improve their printing processes. Different inkjet inks used for industrial printing applications offer a wide range of options for manufacturers to achieve quality printing on various substrates.

Understanding the Different Industrial Inks Available

The use of different inks depends on the substrate that they will be printed on. Here are some of the commonly-used industrial inks:

1. Solvent ink - Solvent inks are suitable for printing on non-absorbent surfaces, such as plastic, metal, and glass. Solvent inks contain volatile organic compounds (VOCs) that evaporate quickly, leaving the pigments behind. The ink is waterproof and can withstand harsh environments.

2. UV-cured ink - UV-cured inks are ideal for printing on materials that are sensitive to heat. The ink is cured using ultraviolet light, resulting in fast drying, high-quality images. UV-cured inks are commonly used in printing on wood, plastic, metal, glass, and ceramics.

3. Water-based ink - Water-based inks are eco-friendly as they contain less VOCs compared to solvent-based inks. They are best suited for printing on porous surfaces such as paper, cardboard, and fabrics. Water-based inks dry slowly but offer bright and vivid colors.

4. Dye-sublimation ink - Dye-sublimation inks are used in the printing of textiles, ceramics, and mugs. The ink is printed on transfer paper and is then placed on the material to be printed. The heat from a press allows the ink to be sublimated onto the surface, resulting in vibrant colors that resist fading.

5. Pigment ink - Pigment inks are commonly used in desktop printers and are also suitable for industrial printing. They are fade-resistant and can produce sharp, long-lasting images. Pigment inks are commonly used for printing on textiles, paper, and plastic.

How to Select the Right Ink for Industrial Printing

Selecting the right ink for industrial use can be challenging, but it's essential to ensure that you get the best results. Here are some of the factors to consider when selecting the right ink for industrial printing:

1. Substrate - The substrate determines the type of ink to be used. For example, printing on plastic requires the use of solvent ink, while printing on paper requires water-based ink.

2. Image quality - The type of ink used determines the quality of the image produced. Pigment inks produce sharp, long-lasting images, while dye-sublimation inks produce vibrant colors.

3. Durability - Industrial printing requires ink that can withstand harsh environments. Solvent inks are waterproof and can withstand harsh weather conditions.

4. Eco-friendliness - An eco-friendly ink is ideal for industrial printing as it reduces the environmental impact. Water-based inks are eco-friendly as they contain fewer VOCs.

5. Cost - The cost of ink is also crucial when selecting the right ink for industrial printing. Solvent inks are the cheapest, while UV-cured inks are the most expensive.

Industrial Inks Applications

Different inks have unique properties that make them suitable for specific industrial printing applications. Here are some of the industrial inks applications:

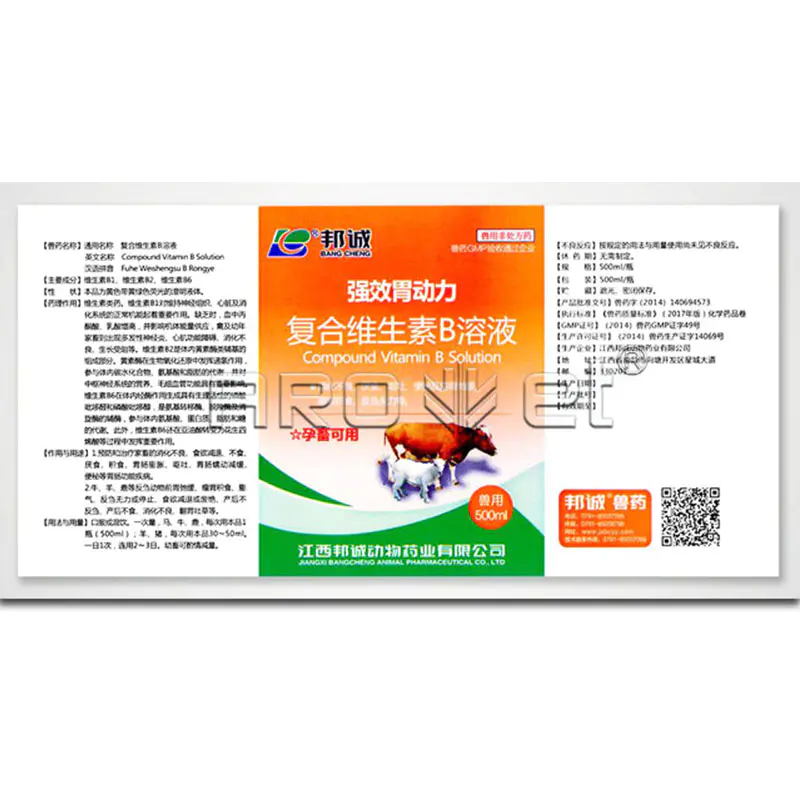

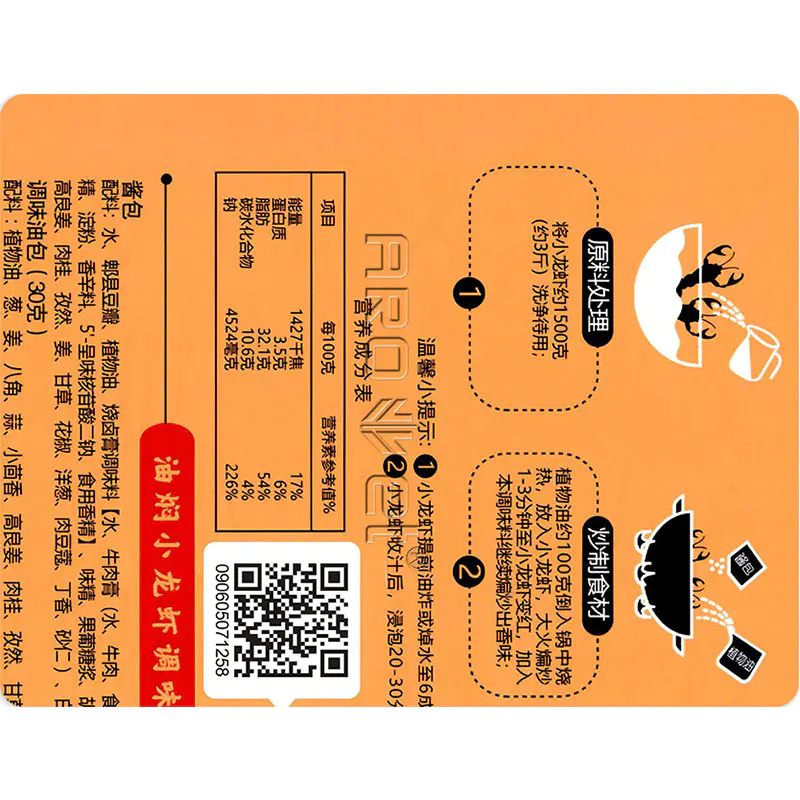

1. Printing on plastic - Solvent inks are the most common in printing on plastic. They are popular in the packaging industry for printing on plastic bottles, containers, and bags.

2. Printing on metal - Solvent inks are also suitable for printing on metal substrates. They are used in the printing of metal containers, cans, and signages.

3. Printing on textiles - Pigment inks and dye-sublimation inks are commonly used in textile printing. They are used in the printing of t-shirts, bags, and banners.

4. Printing on ceramics - Dye-sublimation inks are suitable for printing on ceramics, resulting in bright and long-lasting images.

5. Printing on glass - Glass printing requires the use of UV-cured inks. They are ideal for printing on glass bottles and other glass containers.

Conclusion

Different inkjet inks used for industrial printing applications offer a wide range of options for manufacturers to achieve quality printing on various substrates. The selection of the right ink is crucial in achieving the desired results. Factors such as substrate, cost, eco-friendliness, durability, and image quality should be considered when selecting the right ink for industrial printing. Understanding the properties of each ink ensures that the right ink is selected for industrial printing applications.

arojet@arojet.com

arojet@arojet.com