How does an industrial printer work?

When it comes to printing on a large scale, industrial printers are the go-to solution for businesses. They offer a range of benefits, including increased speed and efficiency, more reliable and consistent output, and the ability to handle a variety of materials. But just how do these machines work? In this article, we’ll take a closer look at the inner workings of an industrial printer and explore some of the key features that make them such an essential asset to modern manufacturing.

Why use an industrial printer?

Before we dive into the specifics of how an industrial printer works, let’s take a moment to consider why a business might choose to invest in one of these machines in the first place. There are a number of reasons why an industrial printer can be a smart investment. Here are just a few:

Increased speed and efficiency: Industrial printers are designed to handle large volumes of printing quickly and efficiently. This means that you can print more in less time, which can be a real advantage for time-sensitive projects.

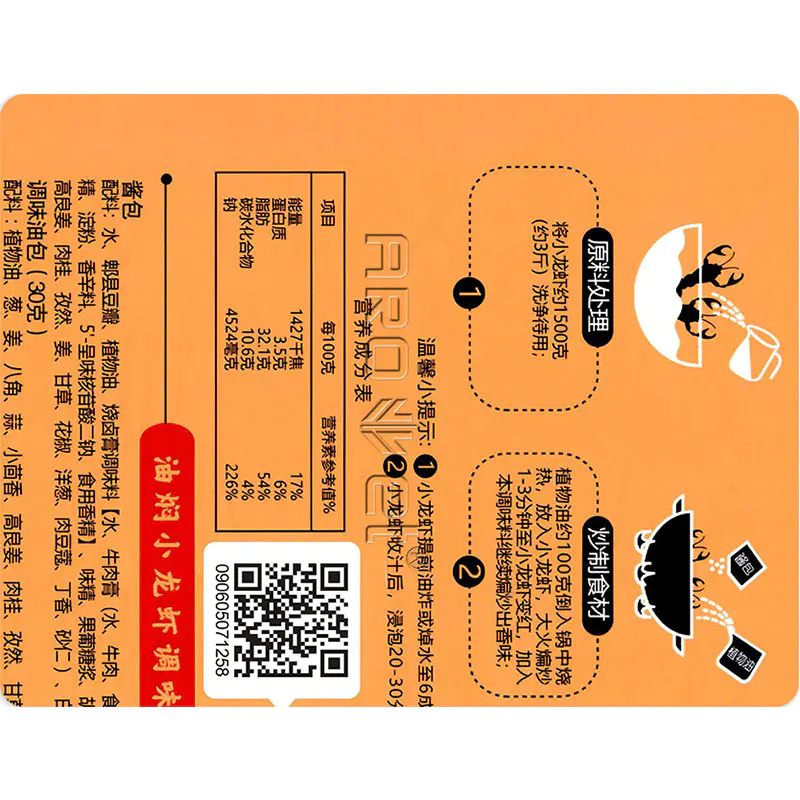

Improved output quality: Industrial printers are often highly precise and accurate, which means that the output quality is typically very high. Whether you’re printing text, images, or barcodes, you can expect a consistent, reliable result every time.

Enhanced flexibility: Industrial printers can usually handle a wide range of materials and can be configured to work with different types of ink or toner. This means that you can use them for a variety of projects and adapt them to suit your specific needs.

Lower cost per unit: If you’re printing on a large scale, you may be able to take advantage of economies of scale to drive down your cost per unit. This can be a real advantage if you need to keep costs under control.

With these benefits in mind, let’s take a closer look at how an industrial printer actually works.

The basics of an industrial printer

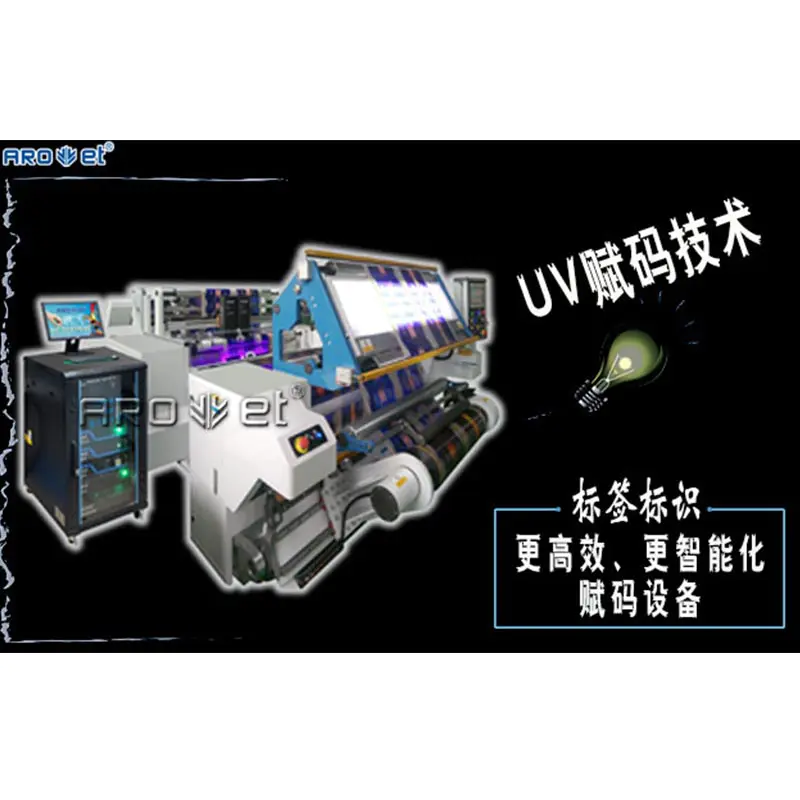

At its core, an industrial printer works much like a standard desktop printer. It uses a combination of ink or toner and a moving print head to apply the desired image or text to a substrate. The main difference, however, is that an industrial printer is usually much larger and more powerful than a desktop printer. It can handle larger print jobs, and it’s built to be more durable and resilient to cope with the demands of industrial use.

When you start a print job on an industrial printer, the first thing that happens is that the substrate (i.e., the material you’re printing on) is fed into the machine. This can be done manually or automatically depending on the specific printer. Once the substrate is in place, the printer applies the ink or toner to the surface using a print head that moves back and forth across the substrate. Depending on the printer, the print head may move in one direction only, or it may move in both directions.

Most industrial printers use some form of digital technology to manage the printing process. This means that the image or text being printed is first converted into a digital format and then transmitted to the printer via a computer or other device. The printer then uses the digital data to apply the ink or toner to the substrate.

Substrates and inks

One of the key advantages of industrial printers is their ability to work with a wide range of substrates and inks. This means that you can print on materials as diverse as paper, plastic, metal, and even fabrics. The choice of substrate will depend on the specific requirements of the project, as well as the capabilities of the printer itself.

Likewise, the type of ink or toner used in an industrial printer can also vary depending on the application. For example, some printers may use UV-curable inks that dry almost instantly on contact with the substrate. Others may use solvent-based inks that are designed to be more durable and resistant to fading over time.

Print heads and resolutions

The print head is a critical component of any industrial printer. This is the part of the machine that actually applies the ink or toner to the substrate. Print heads can vary in size and configuration depending on the printer, but they all operate on the same basic principle: the ink or toner is heated and sprayed onto the substrate in tiny droplets that combine to form the desired image or text.

The resolution of an industrial printer is another key feature to consider. This refers to the level of detail and clarity that can be achieved in the final output. Higher resolutions mean that the printer can create more intricate images and text, but they may also increase the printing time and cost per unit.

Maintenance and repairs

As with any piece of industrial equipment, an industrial printer will require regular maintenance and occasional repairs to keep it running smoothly. This might involve cleaning the print heads, replacing worn parts, or updating the software. It’s important to have a maintenance plan in place to minimize downtime and ensure that the printer remains fully functional.

Conclusion

Industrial printers are a powerful and versatile tool for modern manufacturing. They offer a range of benefits, from increased speed and efficiency to more reliable output and greater flexibility. By understanding the basic workings of an industrial printer, you can make an informed decision about whether one of these machines is right for your business. Whether you’re printing labels, barcodes, or packaging materials, an industrial printer can help you take your production to the next level.

arojet@arojet.com

arojet@arojet.com