-

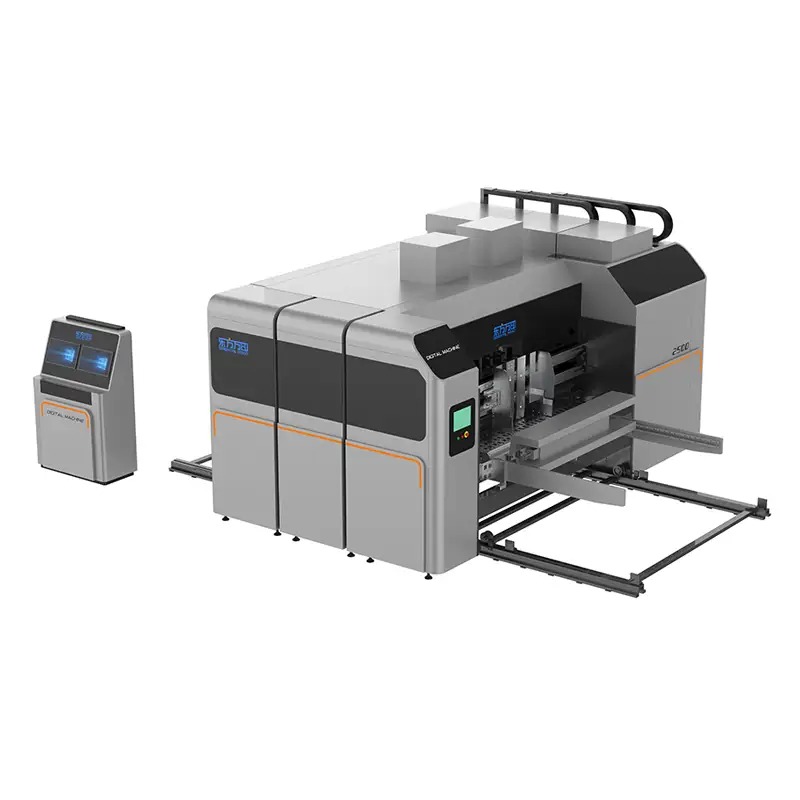

A single pass digital inkjet printer that understands Corrugated cartons

Oriental Print Corrugated cardboard Digital Inkjet Printing machine

-

Product Oerview

Oriental Print DF-1600/2500 Single Pass Industrial Corrugated cardboard CMYK digital Printing machine (Single sheet).

-

Single Pass printing technology brings high production efficiency.

-

High precision industrial piezoelectric inkjet printing technology,inkjet printing accuracy up to 1200x1200dpi.

-

The use of Eco-friendly water-based dye inks, not only good weather resistance and has a good waterproof.

-

Digital inkjet printing production process makes the operation simple, easy to maintain, greatly improve the efficiency of printing production.

-

The use of CMYK four colors to achieve a wide pantone color gamut space, accurate implementation of all colors.

-

More than 100 different types of variable barcodes can be realized with monochrome and color variable data.

-

Apply to different types of corrugated cardboard.

-

Product Features

-

1200dpi high-precision print head configuration

-

The physical resolution of the nozzle is 1200dpi

-

Achieve high-precision printing quality

-

Printing unit module design

-

Multi-group module design, each group can be moved separately

-

Facilitates maintenance of inkjet printing systems for simple and fast maintenance

-

Negative pressure side suction vacuum adsorption

-

The side suction mechanism and the surface of the carton form a wide suction area to generate strong suction air.

-

The flat paper allows the inkjet ink drop point to be more accurate, thereby achieving fine printing effects.

-

Adaptive ink flow control

-

Through the content and production of the printing file, the required ink volume is calculated, and the ink volume system generates the ink flow for printing, avoiding white leakage and stringing in full-page and large-ink printing, making fine printing content more delicate and clear.

-

Secondary drying technology

-

Using 2 colors and one curing, lower energy can produce greater curing effect

-

One-stage curing effectively preheats the carton surface to prevent leaks in large-area printing under different humidity environments. One-stage curing frequently wipes the nozzle to reduce downtime, provide guarantee for long-term stable production, and improve production efficiency.

-

Narrow-edge printing capabilities

-

The control system will automatically switch the suction area on and off according to the paper size.

-

Extend the printing range to a very short distance from the edge of the paper to achieve a full-page printing effect.

-

Vacuum suction dust removal

-

The paper feeding department uses upward suction to remove dust from the cardboard to remove paper scraps and flying dust, prevent white leakage in large-area printing and frequent wiping of nozzles, reduce downtime, provide guarantee for long-term stable production, and improve production efficiency.

-

One box, one code, variable data

-

Powerful variable data capabilities

-

Circulating ink system design: true circulation, true protection

-

The nozzle ink channel circulation ink system

-

achieves sustained and stable printing quality.

-

Rich color expression

-

Accuracy of color management to meet international color needs

-

High resolution, high quality color, high reversibility

-

Micro-peristaltic nozzle maintenance technology

-

Through the circulation pump micro-peristalsis control technology, the ink on the surface of the nozzle is automatically eliminated. There is no need to scrape or manually wipe the surface of the nozzle after inkjet pressing, which greatly reduces the risk of nozzle damage.

-

Multi-stage ink filtration

-

Through multi-stage ink filtration, each stage uses different filtration precision to effectively filter ink impurities and reduce the risk of nozzle clogging.

-

Different filtration precision also ensures that the ink characteristics are not changed and achieves fidelity of printing quality.

-

Unique floor structure design

-

Through the unique design of the nozzle mounting bottom plate, it can overcome the impact of high-speed airflow on the ink dot swing of the inkjet, effectively alleviate the impact of high-speed running airflow, and achieve more perfect printing quality.

-

High-speed multi-core RIP computing

-

Supports standard PDF interpretation engines

-

It can fully interpret the PDF format. Any PDF file can present complete graphics elements and text, ensuring color restoration, avoiding data loss, and ensuring output consistency. Optimized Windows multi-core printing technology can meet the needs of multi-nozzle combinations and high-precision images. , Multi-precision printing mode, to meet the needs of large-volume data jobs, the print buffer management function adopts RIP-while-printing and discarding printing technology, which is not limited by the data volume of Windows, making it easy to output ultra-large images.

-

Product Specifications

|

Model: |

DF-1600 |

Dust removal: |

Brush + upper suction |

|

Print head type: |

Industrial piezoelectric print head |

Baffles: |

The upper and lower left and right baffles are electrically adjustable |

|

Technology: |

Single pass Drop-on-demand inkjet technology |

RIP Software: |

RIP Software |

|

Color Support: |

Single color, 2 color, CMYK |

Control software: |

Oriental Print Inkjet control software |

|

Print head width: |

600mm - 2200mm |

Connector |

Connect to ERP System |

|

Ink: |

Water based Dye ink or pigment ink |

Computer |

Gigabit network, optical fiber transmission |

|

Inkjet resolution: |

600dpi or 1200dpi |

PCB |

Gigabit network |

|

Material Type: |

Kinds of single sheet corrugated board |

Working temperature: |

22-28℃ |

|

Material width : |

Max 1600x3200mm(width*feed paper) Min 450x400mm (width*feed paper) |

Functions |

Cardboard anti-warping detection, adjustable vacuum suction, nozzle automatic cleaning, automatic moisture, cardboard color management, automatic spot color matching |

|

Material Thickness: |

1.5mm - 11 mm |

Humidity |

45-65% RH |

|

Material feeding way: |

Servo leading edge cardboard feeding |

Air supply requirements |

0.6-0.84Mpa |

|

Power supply: |

AC380V 3P+PE50/60Hz |

Mechanical Transmission |

Downward suction conveys corrugated board |

|

File format: |

PDF, EPS, TIFF, JPEG, AI, etc., |

Power supply: |

AC380V 3P+PE50/60Hz |

-

Product Videos

-

Product Applications

Zipper cartons

flat cartons

heavy cartons

lunch boxes

corrugated cartons

airplane boxes

gift boxes

suitcases

-

printing effect display