-

Printing starts from one sheet, no plate making required, available immediately.Timely error correction, variable printing, on-demand printing

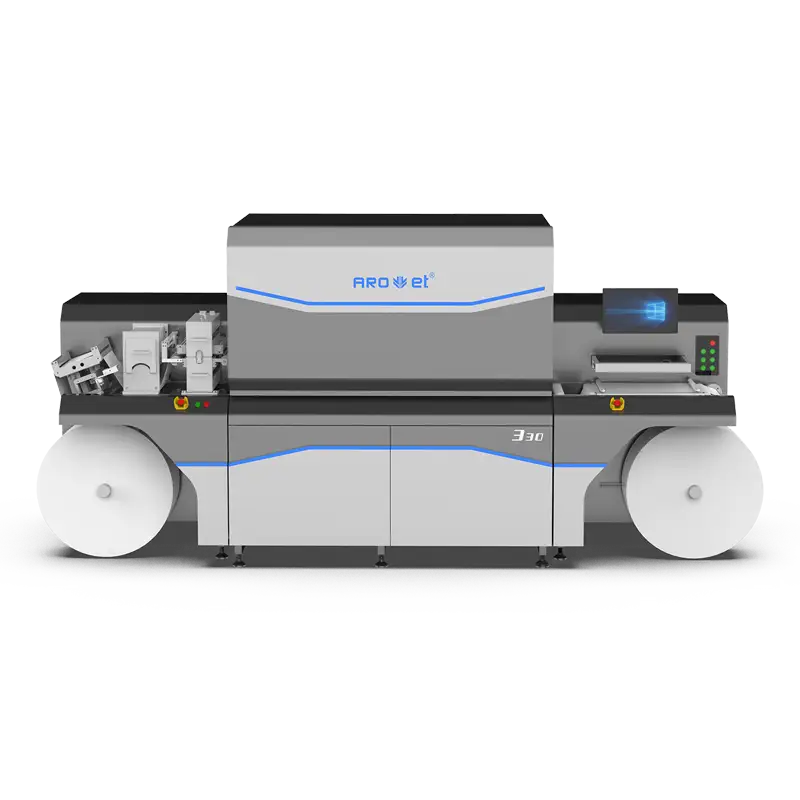

Digital label inkjet printing machine

-

Product Oerview

For label processing companies, Arojet has developed printing equipment covering white and spot colors up to 8 colors, providing higher label printing quality and more accurate color management restoration. It can not only help companies increase business sources and improve example rates, but also It can reduce production costs and simplify traditional complex processes.

In order to meet the production needs of different enterprises and improve the flexibility of digital printing, Arojet has launched a variety of digital inkjet solutions.

*Roll-to-roll standard model

*Digital printing + digital efficiency all-in-one machine

*Digital printing modules (embedded into traditional equipment)

*Flexo printing + digital printing combined model

-

Product design

-

Complete functional design to achieve reliable production guarantee

-

Product Specifications

-

Product Features

Leading industrial-grade inkjet platform

Reliable industrial piezoelectric nozzle design, with high reliability in harsh industrial environments

Fine ink dot design, minimum ink drop size 3pl, suitable for high-definition images, making details richer

Multi-level variable droplet volume is suitable for printing with different image quality requirements. The combination of multi-level droplets makes the color levels more delicate and natural.

Automatic nozzle cleaning and moisturizing

Automatically start nozzle cleaning to shorten downtime for maintenance.

The innovative double cleaning structure cleans the residual ink and dirt on the scraper blade, making the cleaning more thorough and conducive to the protection of the print head.

Automatic moisturizing technology is conducive to long-term shutdown and storage.

High quality ink

Compliant with BS5609 and UL certification, this series of UV inks have good weather resistance, abrasion resistance, chemical resistance and water resistance, and are designed to provide the widest color gamut.

The adhesion provided by our inks eliminates the need for pre-coating or varnishing on most substrate types, saving significant time and money

Reliable ink is beneficial to standby time and continuous printing stability, reducing maintenance times and reducing ink consumption.

Reliable synchronous control technology.

A high-resolution encoder is used to ensure that the printing board and material movement are synchronized.

Unique printing data and motion control technology ensure that nozzle printing and material movement are synchronized.

It achieves high-precision media feeding and improves the overprinting accuracy between nozzles and the uniformity of dots.

High-precision machine mechanism

High-precision roller reduces material bounce and ensures ink droplet ejection shape and accuracy

Closed-loop tension combined with real-time tension compensation eliminates stretch and jitter caused by material movement, allowing ink to be sprayed onto the media more accurately and reducing color unevenness.

Automatic printing module adjustment controls the gap between the print head and the media within the optimal range.

circulating ink system

The circulating ink path system improves the coverage of ink, especially white ink, which is stable at all times.

The ink circulates continuously in the ink path to ensure that the pigment does not settle and eliminates all potential risks of ink and pigment mixing.

Multi-stage circulation eliminates bubbles in the ink in a timely manner, helping to improve printing quality and reliability.

Reliable workflow

Job management

Supports TIFF, EPS, PS, PRN, PDF, JPG, DOC and other file formats

Multiple types of historical file management

Visualized and efficient workflow settings

Material management

Complete material process management database

Accurate process data calling plan

Can meet application needs in many fields

Image Processing

Efficient image RIP process

Simple and easy to use operation process

High quality image output

Quality text edge processing

Unique text edge feathering technology, automatically detects the edges of images and text

Mature ink and material matching solution

Use small and medium ink dots to draw to improve the printing quality of fine lines and text

Color management

Pantone color covers 85%

Comprehensive color ICC matching database

Accurate spot color recognition technology

Variable data printing

Monochrome and color variable data can be realized

Supports over 100 different types of variable barcodes

You can create variable types such as serial numbers, images, text, shapes, garbled characters, etc.

Powerful data management function effectively prevents duplicate codes, garbled codes, and wrong codes from appearing.

Product Videos

-

Product Applications

Beverages, alcohol, food, fruits, medicine, variable data

Daily chemicals, cosmetics, care products, health products, payment, energy efficiency

◇Membrane or film material: PET/PVC/PP/PE/BOPP

◇Foil materials: aluminum, tin and other special materials

◇Paper material: synthetic paper and coated paper