UV inkjet technology means less pre-treatment material and less post-print coating work required compared to other printing technologies, such as flexography, gravure, screen printing and water-based inkjet printing. C2 model brings you both cost-effective and practical inkjet printing solutions.

Arojet AROJET industrial inkjet printing on plastic supplier for film

1. Arojet industrial inkjet printing on plastic is produced by our company with a strong technical force. The product is known for its easy installation and assembly

2. Our quality control system is fully through entire production process of industrial inkjet printing on plastic . The product is the fruit of continuous innovation and improvement

3. It is endowed with important fabric properties for maintaining thermal comforts, such as air permeability, water or moisture (vapor) permeability/transportation and heat transmission. The product covers a wide range of functions

4. This product has a powerful energy bank. During the daylight, it absorbs as much solar light as it can for overnight use. The product is not easy to rust and is highly resistant to harsh conditions

5. This product has a focused reflectivity. Its material prevents full diffusion from occurring to provide greater control over the washout effects of ambient light. The product can run super smoothly and noiselessly

Product Oerview

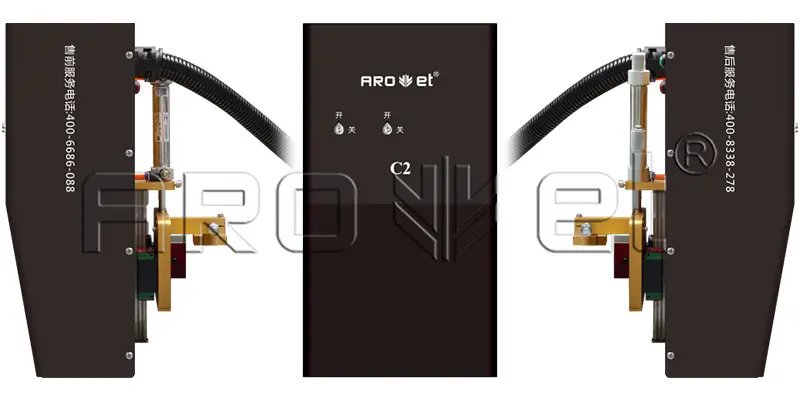

C2 is AROJET model of medium-speed roll or sheet variable data inkjet printing machine, with the printing speed up to 45m/min. 72mm of printhead width makes it suitable for wide-format printing, and a large versatile, cost-reasonable UV inkjet printing applications.

Product Features

◈ Medium-speed, wide-format.

◈ Industrial piezoelectric KONICA 1024 print head.

◈ Seamless stitching, perfect inkjet printing.

◈ Sheet-fed, roll to roll.

◈ Self-designed printing software, streamlined workflow.

◈ Easy operation and simple maintenance.

Product Specifications

Model: | C2 | Printing software: | MagicData variable data-editing software |

Print head type: | Industrial piezoelectric print head (KONICA) | SDK: | Provide interface to support second development |

Print head life: | 100 billion actuations per print head | Ink control: | Negative pressure for ink control, positive pressure for nozzle cleaning |

Print head material: | Stainless steel, Nickel alloys & Epoxy adhesive | Ink type: | High-quality Eco-friendly UV ink |

Print head width: | 72mm (single print head) | Ink color | Single color |

Nozzle quantity: | 1024 pcs (single print head) | Curing type: | UV-LED curing |

Nozzle rows: | 2 rows | Printing speed: | 0-45m/min. (Affected by material, resolution, environment, platform etc. factors) |

Printing modules: | 8 groups | Lengthways printing precision: | 360dpi |

Max. width of printing: | 576mm | Crosswise printing precision: | 200dpi-1200dpi adjustable |

Distance from print head to material: | 0.5mm-2mm | Weight: | 270KG |

Material feeding way: | Single piece, roll to roll | Size: | 1.39m*0.83m*1.50m (print head case+curing case) |

Power supply: | AC 100V-240V, 50Hz-60Hz | Working temperature: | 5°C-40°C |

Interface type: | USB 2.0 | Environment humidity: | 20%-65% RH |

Product Videos

Product Applications

◇ Single sheet or roll to roll feeding platform

◇ Polishing & laminating equipment

◇ Bottle cap machine

◇ Paging machine

◇ Labeling machine

◇ Printing industry for One-dimensional code, two-dimensional Code, identification code, etc.

◇ Paper, film, card, board

◇ Printing iron, glass, ceramics

◇ Food, beverage and wine

◇ Medicine, drug and health care product

◇ Hardware, electronics, daily chemicals, building materials

Print Head

C2 AROJET model uses KONICA piezoelectric 1024 print head. 72mm wide-format printing greatly increases the production efficiency. Fully enclosed water-proof and anti-aging print head has long service life. The print head can print up to 8 kinds of ink droplets with minimum 6pl and maximum 50pl, which has better control over the printed images, reproduce smooth color progressively and accurate match tones. High printing resolution can be achieved. When the printing speed is 30m/min. the resolution reaches 360*300dpi.

The print head for C2 model can be compact installed to improve the printing quality. With its distinctive features of medium speed and wide format, C2 model can satisfy customers from many industries with various data inkjet coding and marking demands.

Printing Software

The MagicData software used in C2 model has gained self-design copyright with strong functions. It can be tailor-made according to customer requirements to satisfy customer versatile demands.

※ Create main interface with intuitive preview

※ Support to load data source file

※ Combine and separate

※ Template management

※ Flexible layout design tools

Printing Ink

AROJET C2 model uses UV curing ink. UV curing is widely adopted in inkjet printing industry. UV curing ink has three major characteristics: energy-saving drying, extensive printing adaptability for printing materials, high-speed curing can shorten the follow-up processing time. The fourth characteristic of UV curing on inkjet printing is digital processing.

With the continuously improvement of the manufacturing and control technology of the inkjet printing, UV printing can meet diversified demands. In addition, UV ink does not include organic solvents, and is completely harmless to both human health and environment. UV ink is becoming more and more popular with many customers.

※ Inkjet printability

※ Anti-scratch, friction resistance and anti-corrosive

※ Hazardous substance content conforms to RoHS standard.

Company Features

1. Over the years, Guangdong AROJET Ink Jet Technology Co., Ltd., backed up by extensive industry experience, has gained a reputation for providing high quality industrial inkjet printing on plastic .

2. By applying most advanced technology, Arojet has made a great influence in the inkjet dod industry.

3. We aim to stay at the forefront of the fight against climate change by setting science-based targets to reduce CO2 emissions from our own manufacturing.