Inkjet Marking for Medical and Pharmaceutical Applications

Inkjet Marking for Medical and Pharmaceutical Applications

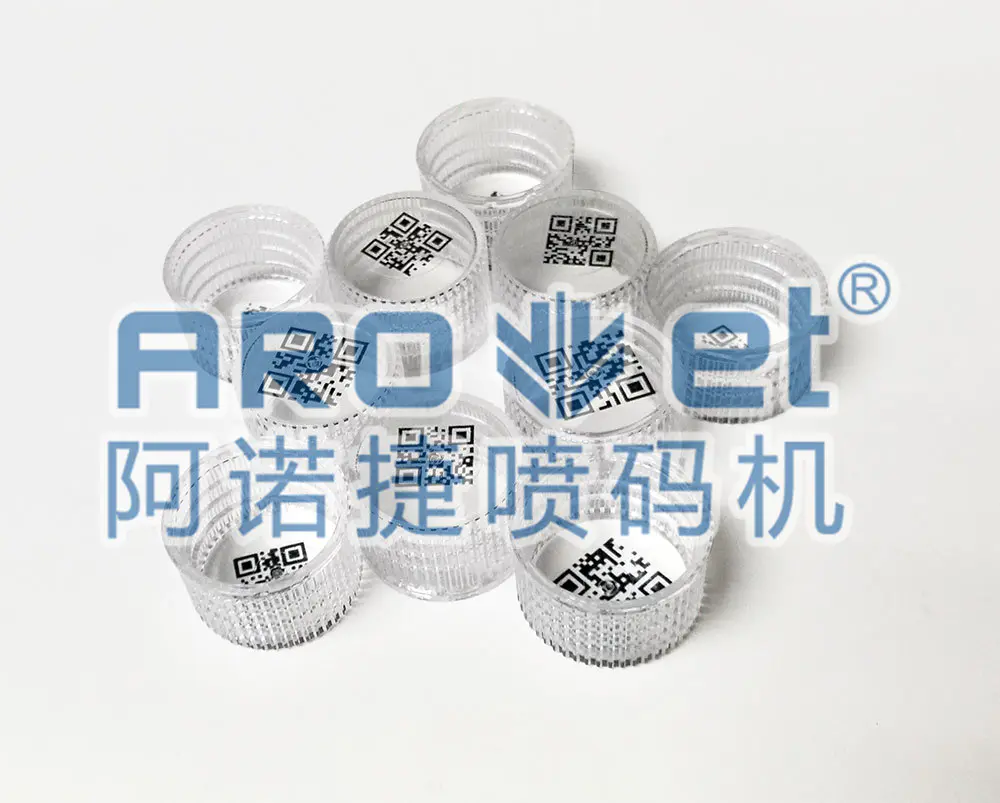

Inkjet technology has revolutionized the way we print and mark products. It is very common for us to encounter products that have been marked with inkjet, such as food packaging, electronics and many more. However, there are industries where inkjet marking plays a crucial role, such as medical and pharmaceutical industries. Inkjet marking provides a reliable, fast and cost-effective way of marking products with crucial information, such as expiration dates, lot numbers and other key data.

In this article, we will explore the benefits of inkjet marking in medical and pharmaceutical applications, including its importance in ensuring product safety and accuracy. We will also look at the different types of inkjet marking methods used in the medical and pharmaceutical industries, as well as the regulations that govern the use of inkjet marking.

Why Inkjet Technology Is Ideal for Medical and Pharmaceutical Applications

Inkjet technology is ideal for medical and pharmaceutical applications for several reasons. First, inkjet printers can mark products with high precision and accuracy. This is important in the medical and pharmaceutical industries, where even tiny mistakes can have huge consequences. Inkjet printers can produce very small print sizes, which is essential for marking small products such as pills and medical devices. Inkjet printers can also produce high-resolution prints, ensuring that the information is legible and clear.

Second, inkjet printing is fast and reliable. This is important in industries where products are produced in large volumes and need to be marked quickly and efficiently. Inkjet printers can mark products at high speeds, and can handle large volumes of products without sacrificing print quality or accuracy.

Third, inkjet printing is cost-effective. Inkjet printers are more affordable than other types of printing equipment, such as thermal transfer printers. This makes inkjet technology more accessible for smaller businesses and startups in the medical and pharmaceutical industries.

Types of Inkjet Marking Methods Used in Medical and Pharmaceutical Applications

There are several types of inkjet marking methods used in medical and pharmaceutical industries. These include:

1. Continuous Inkjet (CIJ) Printing

Continuous Inkjet (CIJ) printing is one of the most commonly used inkjet marking methods in medical and pharmaceutical applications. This method uses a continuous stream of ink droplets that are projected onto the product. The droplets are charged with an electrostatic charge, which determines where the droplets will land on the product. The excess ink is recycled back into the printer, making CIJ printing more environmentally friendly.

CIJ printing is fast and efficient, and can print on a wide range of substrates. It is ideal for printing small text, graphics and barcodes on medical devices, packaging and labels.

2. Drop on Demand (DOD) Printing

Drop on Demand (DOD) printing is another inkjet marking method used in medical and pharmaceutical applications. This method uses a piezoelectric crystal that vibrates and ejects ink droplets onto the product. The ink droplets are only released when needed, which reduces ink wastage and makes DOD printing more cost-effective than CIJ printing.

DOD printing is ideal for printing large characters, logos and graphics on cardboard boxes, bags and other packaging.

3. Thermal Inkjet (TIJ) Printing

Thermal Inkjet (TIJ) printing is a type of inkjet technology that uses heat to eject ink droplets onto the product. TIJ printers use a printhead that heats up the ink, causing it to expand and eject droplets onto the product. TIJ technology is fast and efficient, and produces high-quality prints.

TIJ printing is ideal for printing small text, graphics and barcodes on pharmaceutical packaging and labels.

4. High-Resolution Inkjet Printing

High-Resolution Inkjet (HRIJ) printing is a type of inkjet technology that produces high-resolution prints with very small droplets. This method uses a piezoelectric printhead that can produce droplets as small as 1 picolitre (pl). HRIJ printing is ideal for printing high-quality graphics and small text on medical devices, packaging and labels.

5. UV Inkjet Printing

UV inkjet printing is a type of inkjet technology that uses UV-curable inks to produce prints that are resistant to fading, smudging and water damage. UV inkjet printers use UV lamps to cure the ink, which hardens it and makes it more durable. UV inkjet printing is ideal for printing high-quality graphics and text on medical devices, packaging and labels that require high durability.

Regulations Governing the Use of Inkjet Marking in Medical and Pharmaceutical Industries

The use of inkjet marking in medical and pharmaceutical industries is governed by several regulations and standards, including:

1. US FDA Regulations

The US FDA regulates the use of inkjet marking in medical and pharmaceutical industries. Inkjet markings must be legible and accurate, and must provide essential information such as lot number, expiration date, and manufacturer information.

2. EU Regulations

The European Union (EU) has similar regulations governing the use of inkjet marking in medical and pharmaceutical industries. Inkjet markings must be legible and permanent, and must include essential information such as product name, strength and dosage.

3. ISO Standards

The International Organization for Standardization (ISO) has developed several standards that govern the use of inkjet marking in medical and pharmaceutical industries. These standards include ISO 11607-1, which provides guidelines for packaging and labelling of medical devices, and ISO 15415, which specifies the quality of barcodes used in pharmaceutical applications.

Conclusion

Inkjet marking plays a crucial role in ensuring safety and accuracy in medical and pharmaceutical industries. Inkjet technology provides a reliable, fast and cost-effective way of marking products with essential information such as lot number, expiration date and other key data. There are several types of inkjet marking methods used in medical and pharmaceutical applications, each suited for different types of products and applications. In addition, regulations and standards govern the use of inkjet marking in medical and pharmaceutical industries, ensuring that the information is accurate, legible and permanent.

arojet@arojet.com

arojet@arojet.com