What is industrial inkjet printing

Industrial Inkjet Printing: Revolutionizing the Printing Industry

Introduction:

With the constant advancements in technology, the printing industry has undergone a significant transformation. Traditional methods of printing have given way to more efficient and versatile techniques, and one such breakthrough is industrial inkjet printing. Unlike conventional methods that involve the transfer of ink to paper using plates, industrial inkjet printing utilizes modern digital technology to produce high-quality prints on a wide range of surfaces. In this article, we will explore the intricacies of industrial inkjet printing, its applications, benefits, and future prospects.

Understanding Industrial Inkjet Printing

Industrial inkjet printing involves the use of specialized printers that employ tiny nozzles to spray ink onto a printing substrate. Instead of using plates or screens, these printers use digital files to guide the precise placement and volume of ink droplets, resulting in superior print quality. The nozzles accurately control the flow of ink, allowing for precise saturation and sharpness. This technology allows printing on various surfaces like paper, textiles, ceramics, glass, metal, and even three-dimensional objects.

Applications of Industrial Inkjet Printing

2.1 Packaging and Labeling:

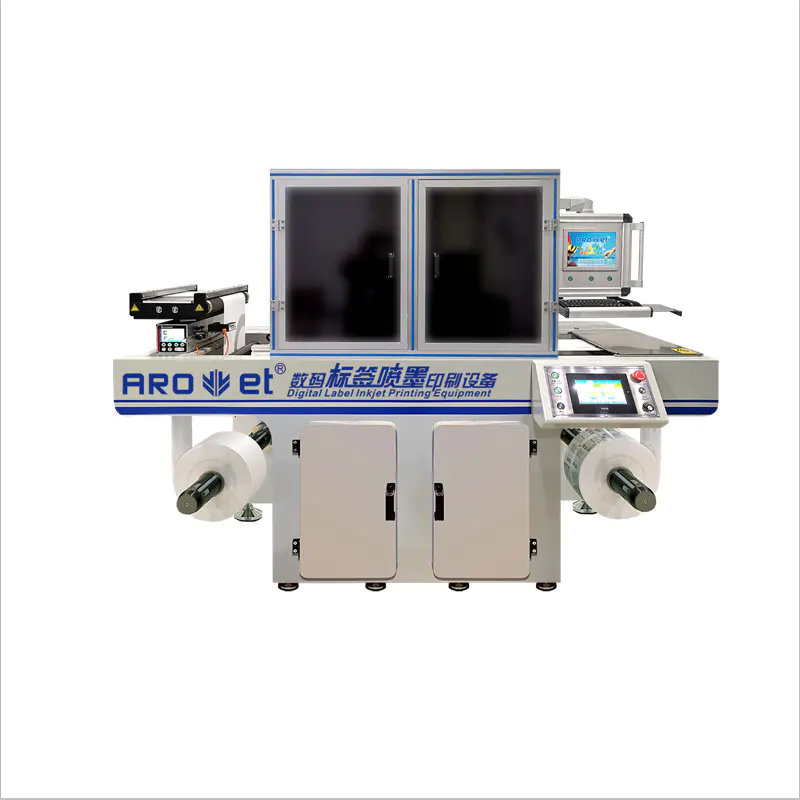

Industrial inkjet printing has revolutionized the packaging and labeling industry. The ability to print on various substrates, combined with high-speed production capabilities, has made it the preferred choice for brand owners and manufacturers. From customized labels and barcodes to variable data printing, industrial inkjet printing provides flexibility and cost-efficiency.

2.2 Textile Manufacturing:

Textile printing has also witnessed a substantial shift due to industrial inkjet printing. The technique has enabled the production of vibrant and detailed designs on various fabrics without compromising on production speed. Customization options, such as variable patterns and color gradients, have garnered attention from fashion designers and manufacturers globally.

2.3 Signage and Advertising:

Industrial inkjet printing has transformed the way signs and advertisements are produced. With the ability to print on a wide range of substrates, including vinyl, plastic, metal, and even glass, businesses can create visually captivating displays with ease. Outdoor signage, vehicle wraps, and promotional banners now boast enhanced durability and vibrant colors, thanks to industrial inkjet printing.

2.4 Ceramic Printing:

Traditional methods of ceramic printing were time-consuming and limited in terms of design possibilities. However, industrial inkjet printing has brought a new era to ceramic production. Intricate designs, textures, and even photographic images can now be printed directly onto ceramic surfaces. This advancement has greatly influenced the tile and interior d茅cor industries.

2.5 Functional Printing:

Industrial inkjet printing is not limited to visual aesthetics; it also caters to functional printing needs. This technology allows for the deposition of conductive inks to create circuits, sensors, and electronic components. The ability to print electronics directly onto various substrates opens up new possibilities for industries such as healthcare, automotive, and electronics.

Advantages of Industrial Inkjet Printing

3.1 Cost-effective Production:

The digital nature of industrial inkjet printing eliminates the need for expensive printing plates, screens, or molds. This reduction in setup costs makes it an economical option for short print runs or variable data printing. Additionally, the ability to print directly on substrates reduces material waste, saving both time and money.

3.2 Enhanced Quality and Detail:

Industrial inkjet printing offers unparalleled print quality, surpassing traditional methods. The precision and control over ink droplet placement result in sharper images, finer details, and vibrant colors. The elimination of physical contact with printing surfaces minimizes the risk of smudging or smearing, ensuring consistently high-quality prints.

3.3 Quick Turnaround:

Due to its digital nature, industrial inkjet printing allows for rapid prototyping and production. Traditional printing methods often required lengthy setup times and manual adjustments. With industrial inkjet printing, the digital files can be quickly processed, and designs can be modified on the fly, resulting in shorter production cycles.

3.4 Versatility:

One of the key advantages of industrial inkjet printing is its ability to print on a wide range of substrates. From paper to ceramics, glass to textiles, the possibilities are limitless. This versatility allows businesses to explore new markets, cater to diverse customer demands, and offer personalized products.

3.5 Eco-friendly Printing:

Industrial inkjet printing is considered an eco-friendly alternative to traditional printing methods. The elimination of chemical processes and the ability to print directly on substrates significantly reduces waste generation. Additionally, the digital nature of this technology reduces energy consumption and carbon emissions when compared to conventional printing procedures.

Future Prospects of Industrial Inkjet Printing

The future of industrial inkjet printing looks promising, with continual advancements in technology and innovation. Here are some exciting possibilities:

4.1 3D Printing:

The integration of industrial inkjet printing and 3D printing is a game-changer. Combining the ability to deposit colors, textures, and patterns directly onto 3D-printed objects will open up new opportunities for product customization and personalization.

4.2 Bio-printing:

The healthcare industry can benefit from industrial inkjet printing in the field of bio-printing. Researchers are working on using specialized inks to print living tissues and organs, revolutionizing the medical field by enabling organ transplants without the need for donors.

4.3 Functional Electronics:

As technology continues to evolve, industrial inkjet printing will play a vital role in the production of flexible and wearable electronics. The direct deposition of conductive inks to create circuits and sensors will pave the way for smart clothing, wearable health monitors, and interactive surfaces.

Conclusion:

Industrial inkjet printing has transformed the printing industry, offering superior print quality, versatile applications, and a more sustainable approach to production. Its ability to print on various substrates combined with cost-efficiency and rapid turnaround times makes it the technology of choice for numerous industries. As innovations continue to unfold, industrial inkjet printing is set to revolutionize various sectors, ranging from healthcare to fashion, and unlock endless opportunities for customization and creativity. Embracing this technology will undoubtedly lead to enhanced productivity and customer satisfaction in the ever-evolving world of printing.

arojet@arojet.com

arojet@arojet.com