High-Resolution Printing Output of Industrial UV Printers

Article

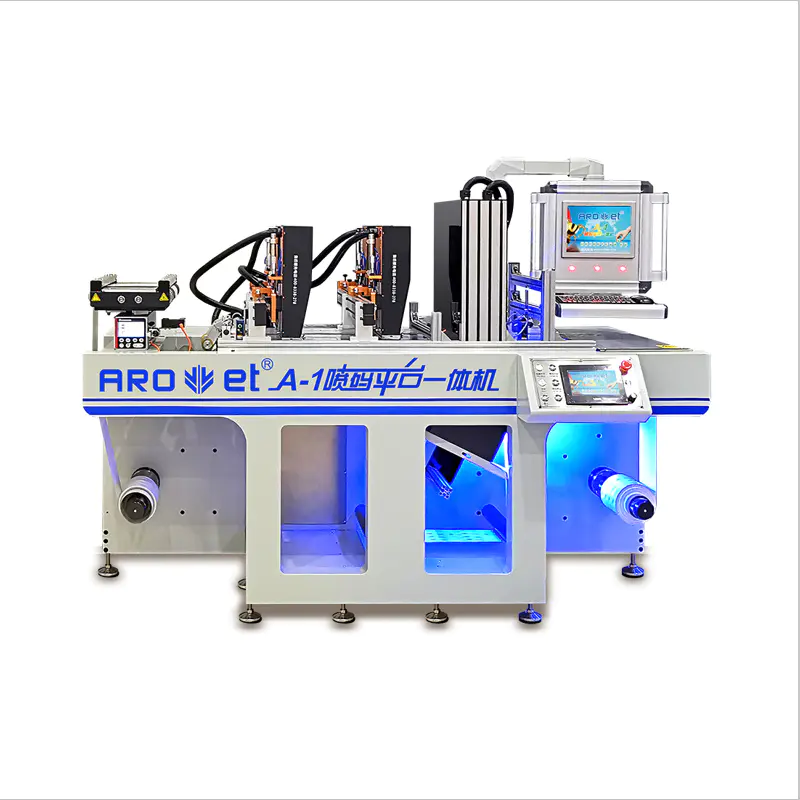

1. Introduction to High-Resolution Printing in Industrial UV Printers

2. Understanding the Technology Behind High-Resolution UV Printing

3. Advantages of High-Resolution Printing in Industrial UV Printers

4. Applications and Industries Benefiting from High-Resolution UV Printing

5. Tips for Achieving Optimal High-Resolution Printing Output in Industrial UV Printers

Introduction to High-Resolution Printing in Industrial UV Printers

With the advancement of technology, high-resolution printing has become a crucial requirement in various industries. The ability to produce detailed and vibrant prints is especially important in fields like advertising, packaging, and signage. Industrial UV printers have emerged as a reliable solution for achieving exceptional print quality. This article explores the technology behind high-resolution UV printing, its advantages, applications, and provides useful tips for optimizing the printing output.

Understanding the Technology Behind High-Resolution UV Printing

UV printing, also known as ultraviolet printing, utilizes UV curable inks that are instantly cured or dried using UV light. Industrial UV printers employ a sophisticated printing process that ensures high-resolution output. The printing process starts with the creation of digital image files, which are later transferred to the UV printer. The printer uses a combination of UV curable inks and UV light to rapidly cure the ink and fix it to the substrate.

To achieve high-resolution printing, industrial UV printers utilize advanced printhead technology and precise ink droplet placement. Modern printers adopt printheads with a high number of nozzles, capable of jetting tiny ink droplets onto the substrate. These nozzles are designed to accurately fire the droplets, resulting in fine details and smooth gradient transitions.

Advantages of High-Resolution Printing in Industrial UV Printers

1. Exceptional Print Quality: High-resolution printing enables the reproduction of intricate designs, sharp texts, and vibrant colors, resulting in visually stunning prints. For industries like advertising and packaging, where aesthetics play a critical role, high-resolution UV printing is indispensable.

2. Versatility: Industrial UV printers offer versatility in terms of printing on a vast range of materials, including wood, glass, metal, textiles, and plastics. The ability to achieve high-resolution printing on diverse substrates expands the possibilities for creative and innovative applications.

3. Durability and Longevity: UV-cured inks used in industrial UV printers offer excellent durability and longevity. These cured inks have enhanced resistance to fading, scratching, and weathering, rendering the prints suitable for outdoor applications and ensuring their longevity.

4. Faster Production: High-resolution printing in UV printers can be achieved at faster printing speeds without compromising print quality. This allows businesses to meet tight deadlines and increase overall productivity.

5. Environmentally Friendly: UV printing is an eco-friendly choice, as it requires low volatile organic compound (VOC) inks that are free from harmful solvents. Additionally, as the ink curing is done instantly, no drying time is needed, minimizing energy consumption during the printing process.

Applications and Industries Benefiting from High-Resolution UV Printing

1. Advertising and Signage: High-resolution UV printing is extensively used in the advertising and signage industry for producing eye-catching banners, billboards, and point-of-sale displays. The ability to achieve vibrant colors and detail-rich prints ensures high visibility and attracts attention.

2. Packaging: In the packaging industry, high-resolution UV printing is employed for creating visually appealing labels, boxes, and packaging materials. Brands can showcase intricate designs, logos, and product information, resulting in an enhanced shelf presence.

3. Interior Design and D茅cor: Industrial UV printers enable high-resolution printing on various surfaces, including ceramics, glass, wood, and metal. This makes them ideal for producing customized wallpapers, home d茅cor, furniture, and personalized promotional products.

4. Textile and Fashion: High-resolution UV printing on textiles opens up new opportunities for the fashion industry. Designers can print intricate patterns, illustrations, or even photographs directly onto fabrics, allowing for personalized and unique garments.

5. Industrial Manufacturing: UV printing plays a critical role in industrial manufacturing processes, including the automotive, aerospace, and consumer electronics sectors. It enables the printing of control panels, labels, and highly detailed components, improving branding and traceability.

Tips for Achieving Optimal High-Resolution Printing Output in Industrial UV Printers

1. Calibration and Maintenance: Regular calibration and maintenance of UV printers are essential to ensure consistent and accurate high-resolution prints. Consult the printer manufacturer's guidelines and follow recommended maintenance schedules for printheads, ink systems, and curing units.

2. Optimal File Preparation: Pay attention to image resolution, color profiles, and file formats to ensure optimal print results. Utilize high-resolution images and vector graphics whenever possible, and convert them to appropriate color spaces for accurate color reproduction.

3. Material Selection: Different materials have varying levels of ink absorption and surface characteristics. Ensure that the printing substrate is suitable for high-resolution UV printing. Conduct tests on different materials to determine the optimal settings and achieve desired results.

4. Printing Parameters: Adjusting print settings such as print mode, droplet size, and curing intensity can significantly impact print quality. Experiment with different parameters to find the optimal balance between speed and resolution for each print job.

5. Quality Control: Implement thorough quality control measures to identify and rectify printing issues. Regularly check prints for color accuracy, sharpness, and image artifacts. Use color management tools like spectrophotometers to ensure consistent prints throughout production runs.

In conclusion, high-resolution printing output in industrial UV printers has revolutionized the printing industry by providing exceptional, detailed, and vibrant prints. The advanced technology, coupled with its numerous advantages, has benefitted various industries ranging from advertising and packaging to interior design and textile. By following the provided tips, businesses can optimize their UV printing output and achieve superior, high-resolution results.

arojet@arojet.com

arojet@arojet.com