AROJET industrial inkjet printer suppliers - a high-tech enterprise for industrial inkjet printing solutions

AROJET industrial inkjet printer suppliers - a high-tech enterprise for industrial inkjet printing solutions

Product Oerview

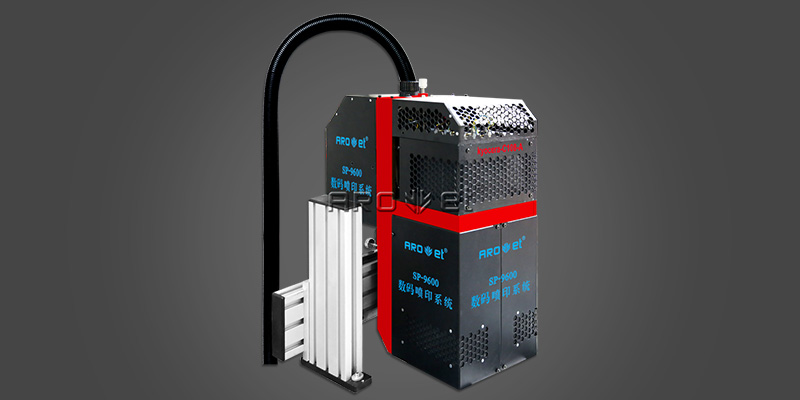

AROJET SP-9600 wide-format digital variable data UV inkjet printing machine adopts KYOCERA industrial piezoelectric printhead with 108mm wide-format configuration. A small number of printheads can be used to achieve large format inkjet printing, to reduce complicated location adjustment. The printing speed is up to 150mm/min. with photo level resolution and minimum text height of 1mm. High image quality and high resolution and grayscale can be gained.

The UV curing ink used can be printed directly on various materials, suitable for a large variety of printing materials, such as printing variable barcode, two-dimension code, character, number, etc. on glass, acrylic, wood board, ceramic tile, metal plate and so on.

SP-9600’s human-friendly software and optional streamlined printing modes, adapt to industrial online production, and meet customers more extensive inkjet printing requirements.

Product Features

◈ Wide-format inkjet printing, reduce number of printhead.

◈ Resolution: 600*300dpi, speed: 150m/min.

◈ Resolution: 600*400dpi, speed: 100m/min.

◈ Resolution: 600*600dpi, speed: 60m/min.

◈ KYOCERA print head, durable,long life and high quality.

◈ Excellent blackness and high definition.

◈ Outstanding inkjet printing stability.

◈ The minimum character height printed is 1mm.

◈ Can both be installed in customer’s production line and be self-equipped platform

◈ 24*7 hours continuous running, improving production efficiency.

Product Specifications

Model: | SP-9600 | Printing software: | MagicData variable data-editing software |

Print head type: | Industrial piezoelectric print head (KYOCERA) | SDK: | Provide interface to support second development |

Print head life: | 100 billion actuations per print head | Ink control: | Negative pressure for ink control, positive pressure for nozzle cleaning |

Print head material: | Stainless steel, Nickel alloys & Epoxy adhesive | Ink type: | High-quality Eco-friendly UV ink |

Print head width: | 108mm (single print head) | Ink color | Single color |

Nozzle quantity: | 2656 pcs (single print head) | Curing type: | UV-LED curing |

Nozzle rows: | 4 rows | Printing speed: | 0-150m/min. (Affected by material, resolution, environment, platform etc. factors) |

Printing modules: | 4 groups | Lengthways printing precision: | 600dpi |

Max. width of printing: | 864mm | Crosswise printing precision: | 200dpi-1200dpi adjustable |

Distance from print head to material: | 0.5mm-2mm | Weight: | 270KG |

Material feeding way: | Single piece, roll to roll | Size: | 1.39m*0.83m*1.50m (print head case+curing case) |

Power supply: | AC 100V-240V, 50Hz-60Hz | Working temperature: | 5°C-40°C |

Interface type: | USB 3.0 optical fiber data transmission | Environment humidity: | 20%-65% RH |

Product Videos

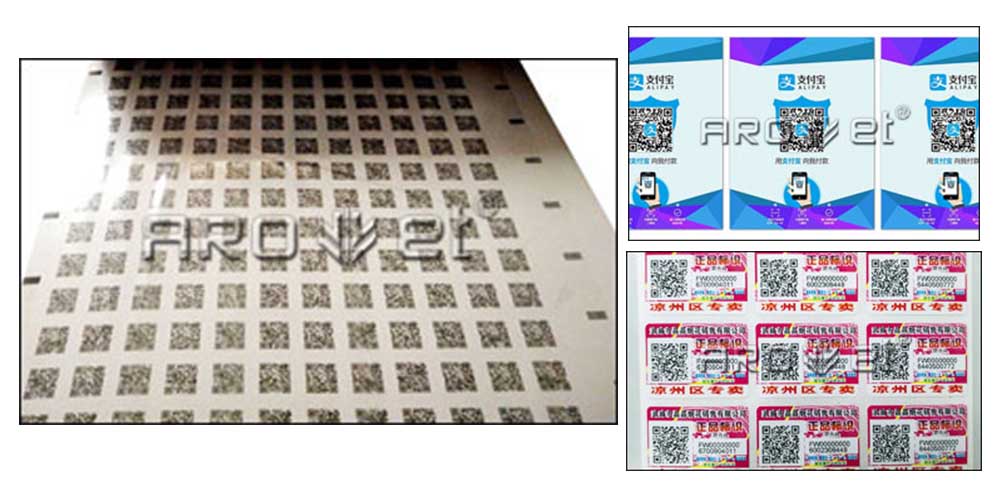

Product Applications

◇ High-speed flexographic press

◇ High-speed full rotary label printing machine

◇ High-speed gravure press

◇ Automatic inspection machine

◇ High-speed slicing & slitting machine

◇ Varnishing and laminating machine

◇ Paging machine

◇ Plastic, wallpaper, advertising cloth, glass, wooden board, ceramic tile, metal plate, PVC plate, corrugated board, etc.

◇ Variable two-dimension code, one-dimension code, character, number, image, etc.

◇ Textile and clothing

◇ Electronics, hardware

◇ Food, beverage and wine

◇ Medicine, drug and health care product

Print Head

SP-9600 model adopts KYOCERA industrial piezoelectric print head, with 108mm wide format, which can print much wider content with fewer print heads. Dense ink droplet stable jetting with 2656 nozzles per head and high image quality of 600dpi and five-level grayscale, enable it to achieve high precision and high definition printing effect and bring new opportunities for your business expansion.

※ Ceramic nozzle, high resolution and long service life.

※ Four kinds of ink droplet size.

※ Powerful nozzle compensation function.

※ Automatic substrate thickness measurement. Printed substrate thickness can be up to 50mm.

Printing Software

Model SP-9600 adopts AROJET MagicData printing software, which is customized for variable data inkjet printing. It offers a human-friendly interface to interactively set printer options, manage and maintain print head, and monitor printing status. With easy operation and maintenance of the printer, MagicData greatly enhance print productivity and efficiency. The software provides interface to support the second development, to achieve versatile inkjet printing applications.

※ Ink drop size setting.

※ Print head temperature setting.

※ Automatically print selected job in fast mode.

※ Customized template and layout design.

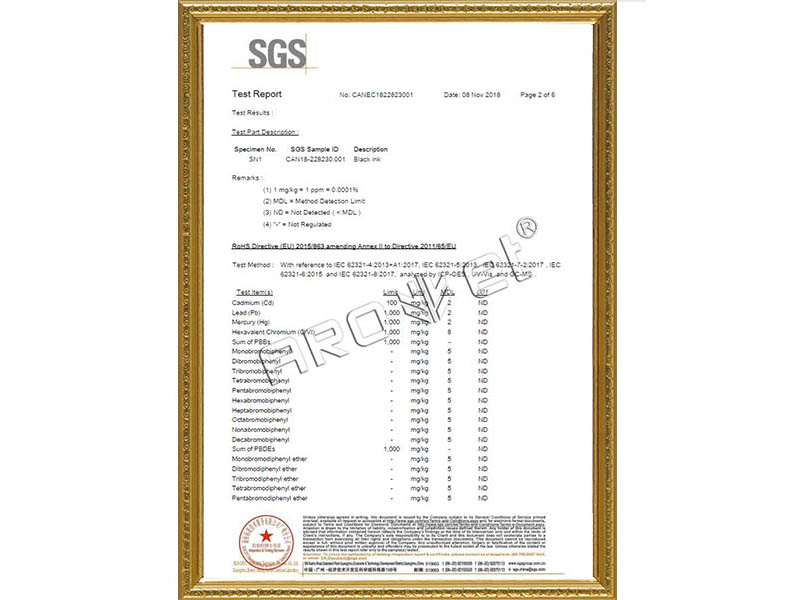

Printing Ink

AROJET wide-format inkjet printer model SP-9600 uses high-quality UV ink. Compared to ordinary ink, UV ink has relatively stable physical properties. It is non-flammable, safe and convenient to transport and use, with no corrosion and no volatility. After inkjet printing, the UV printed content passes through the UV-LED curing system very fast to achieve quick drying. The cured UV ink is high-adhesion, anti-corrosion and friction-resistant with good uniformity, high vivid and excellent quality. UV ink is widely applied to printing industry, provides more delicate and high quality printing to many industries.

AROJET attaches great importance to the ink safety, provides MSDS report of the ink and conducts regular SGS testing for the inks.

※ Eco-friendly. The ink test result conforms to RoHS standard.

※ Outstanding printing adaptability.

Copyright © 2019 Guangdong AROJET Ink Jet Technology Co., Ltd. | All Rights Reserved Design

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.